Meridian Laboratory’s Custom Molded Polyurethane Process

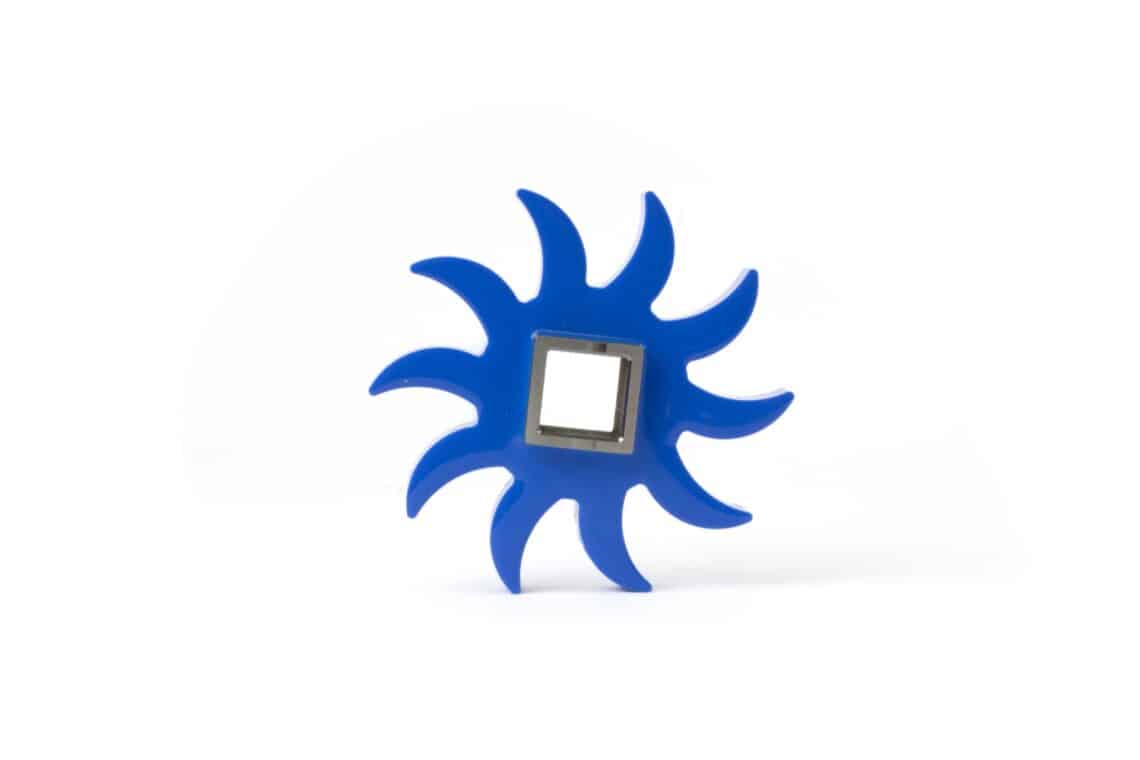

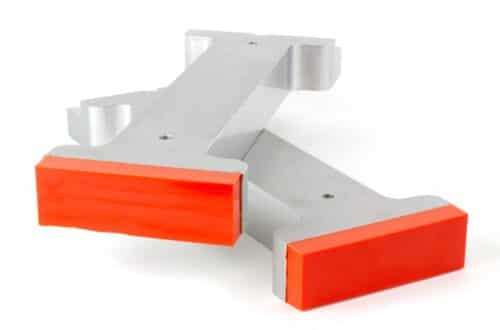

Meridian Laboratory has made the process of developing custom cast and custom molded polyurethane components easy and efficient.

- Contact Meridian Laboratory with your specifications, drawings, or the part you wish to have made/replaced.

- If you require unique tooling to meet your requirements, there may be a one-time setup charge (generally between $250 and $500), and is good for the lifetime of the parts’ dimensions.

- Specify if you would like to have Meridian Laboratory deliver complete with the core, or rather send parts in.

- Typically, in 10-15 business days you will receive your first parts for testing and evaluation.

- As demand and quantities scale, so can Meridian Laboratory’s output and production capabilities to meet your needs.

The ML6 Polyurethane Difference

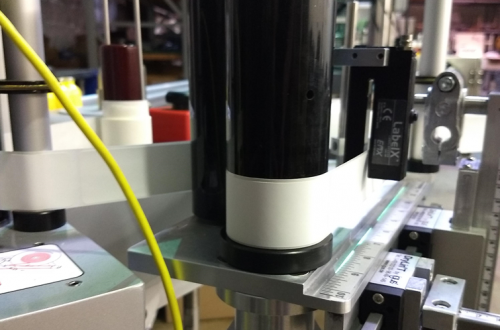

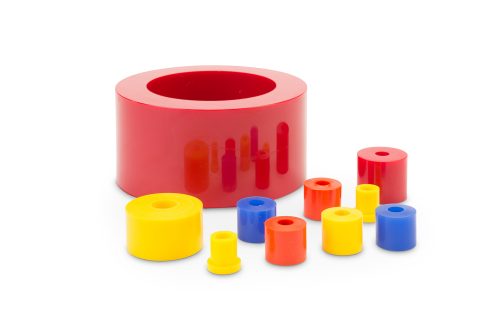

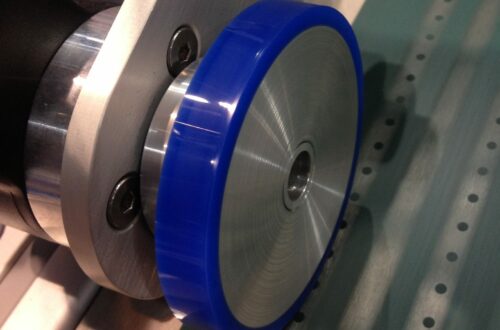

ML6 precision polyurethane is guaranteed to deliver exacting tolerances and precision of up to 0.001” and specified to meet your application’s specific needs. Our combination of engineering and polymer expertise produces a finished product without surface grinding and is free of pits, air bubbles, or other defects that are common in the vast majority of polyurethane products available on the market.

We deliver the results to our customers’ demands of their applications and look forward to solving your custom polyurethane manufacturing needs.

Find out how we deliver unparalleled precision.

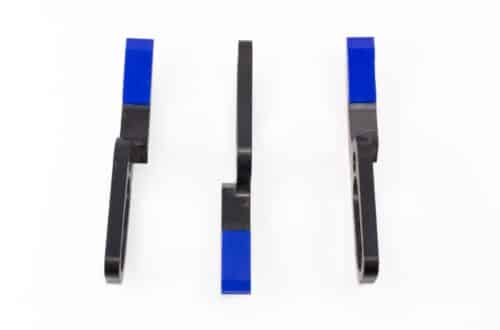

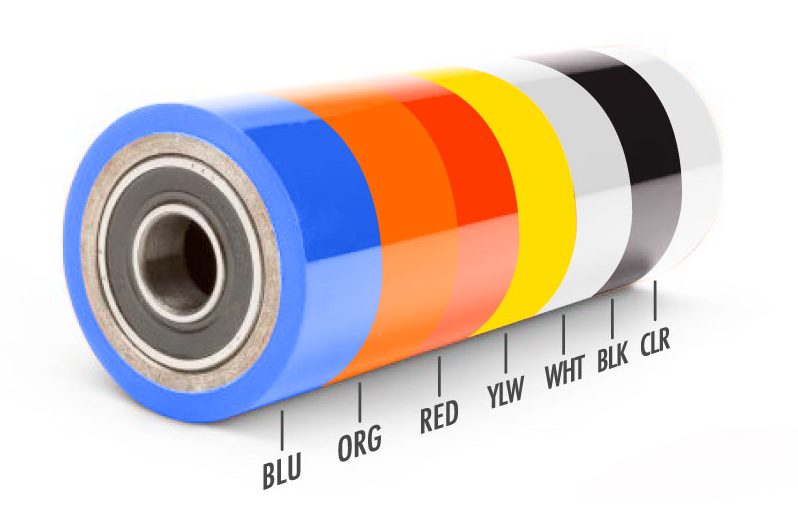

Custom colors available on request

| ML6-40A | ML6-55A | ML6-70A | ML6-80A | ML6-90A | ML6-60D | |

|---|---|---|---|---|---|---|

| Hardness (+/- 5) | 40A | 55A | 70A | 80A | 90A | 60D |

| Ultimate Elongation (%) | 640 | 540 | 540 | 640 | 500 | 300 |

| Ultimate Tensile (PSI) | 3200 | 5300 | 5600 | 6900 | 6200 | 6400 |

| Tear Strength, pli Die "C" | 150 | 244 | 332 | 421 | 568 | 620 |

| Split | 19 | 51 | 92 | 175 | 134 | 125 |

| Compression Modulus (Young's Modulus) | 380 | 830 | 1660 | 1990 | 6460 | 16200 |

| Compression Set (% 22 Hrs. @ 158ºF) | 0 | 1 | 7 | 16 | 18 | 30 |

| Bashore Rebound (%) | 50 | 41 | 37 | 31 | 35 | 52 |

| Abrasion Loss, mm | 200 | 224 | 159 | 94 | 101 | 115 |

For more information, contact Meridian Laboratory