| RPM | Model dependent, see model specifications below* |

| MOUNTING | End of shaft with threaded stud or flange, or with set screws onto shaft (through-hole ERGT Series) Click here for installation and best practices video. |

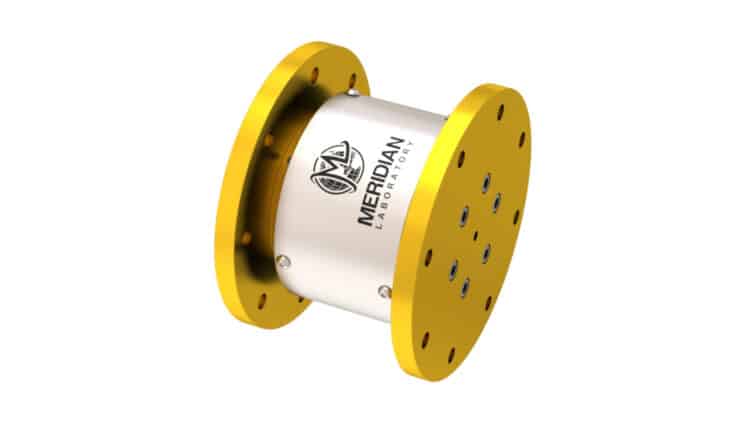

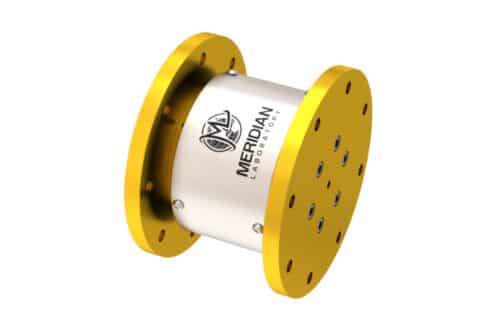

| HOUSING | 304 Stainless Steel |

| OPERATION | Can be operated in any direction or orientation |

| MAINTENANCE | Features permanently lubricated bearings, brush-free design requires no user maintenance |

ERG-3000 Model Specifications

| AMPERAGE | Model dependent, see specifications chart - 100% overload allowed for <60 seconds |

| FREQUENCY | DC to 1GHz - Contact Meridian Laboratory for ampacity ratings at higher frequencies |

| STATIONARY CONTACT RESISTANCE | <0.01mΩ |

| ROTATING CONTACT RESISTANCE | Same as stationary contact resistance (<0.1mΩ) |

| ELECTRICAL NOISE | <0.01uV |

| OPERATION | Intrinsically immune to internal arcing |

ERG-3000 Model Specifications

Video: Installing Your ROTOCON ERG Series High Current Rotary Ground

This video shows installation and best practices when installing your ROTOCON ERG Series, high current rotary ground. Meridian Laboratory’s full lineup of single contact, high current rotary grounds provide a consistent, maintenance-free contact unaffected by RPM or total number of revolutions. Contrary to conventional brushed rotary grounds, Meridian Laboratory’s ERG Series are arc-free, do not have internal friction, and do not require greasing or any type of maintenance.

- Custom mounting flanges

- Liquid cooling for high-temperature applications