Blog / 2020.04.10

White Paper: The Importance Of Contact Resistance In Slip Rings

ROTOCON® Brushless Slip Rings Consistently Deliver Low and Stable Electrical Resistance

Our engineers are regularly called upon to explain and demonstrate the importance of contact resistance, and the signal quality one can expect from a conventional brushed slip ring compared to a ROTOCON brushless slip ring.

Choosing the right slip ring is vital for ensuring reliable results, and delivering the lowest possible maintenance expenses. This dialogue usually begins with a simple but important client question: which device works best for my application? Based on our 55+ years of experience delivering thousands of slip ring solutions, we can help.

In this White Paper we go over the basics of resistance, and what it means for your application.

Contact Resistance White Paper

Author: Dakotah Barnes | Electrical Design & Test Engineer

Table of Contents:

1.1 INTRODUCTION

1.2 WHAT IS ELECTRICITY

1.3 IMPORTANCE OF THE MATERIAL THAT YOU ARE USING

1.4 WHAT IS RESISTANCE AND HOW IS IT MEASURED

1.5 WHAT IS CONTACT RESISTANCE

1.6 IMPORTANCE OF CONTACT RESISTANCE FOR A DEVICE

1.7 CONTACT RESISTANCE AND SLIP RINGS

1.8 HOW DOES THIS EFFECT MY APPLICATION

1.9 HOW IS A ROTOCON® UNIQUE COMPARED TO A TRADITIONAL SLIP RING

1.1 White Paper Introduction

Meridian Laboratory is a global automation and machine component designer, and manufacturer of ROTOCON® brushless slip rings since 1963. A slip ring (and otherwise commonly referred to as a rotary electrical joint, rotary electrical connection, electrical joints, commutators, rotary transmitter, rotary connector, and many other terms) is a device that allows energy flow between a rotating end and a stationary piece of equipment, such as a turntable.

Conventional brushed slip rings rely on stationary graphite or a metal contact (brush) which rubs on the outside diameter of a rotating metal ring. It is important to note, within this document, that every ROTOCON features a brushless, oil-sealed, viscous wetted contact.

This document shares insight on contact resistance and electrical noise relative to slip rings, also in-depth background information on resistance and how it can affect data speeds, signal quality, and voltage readings (if reading an analog sensor).

1.2 What is Electricity

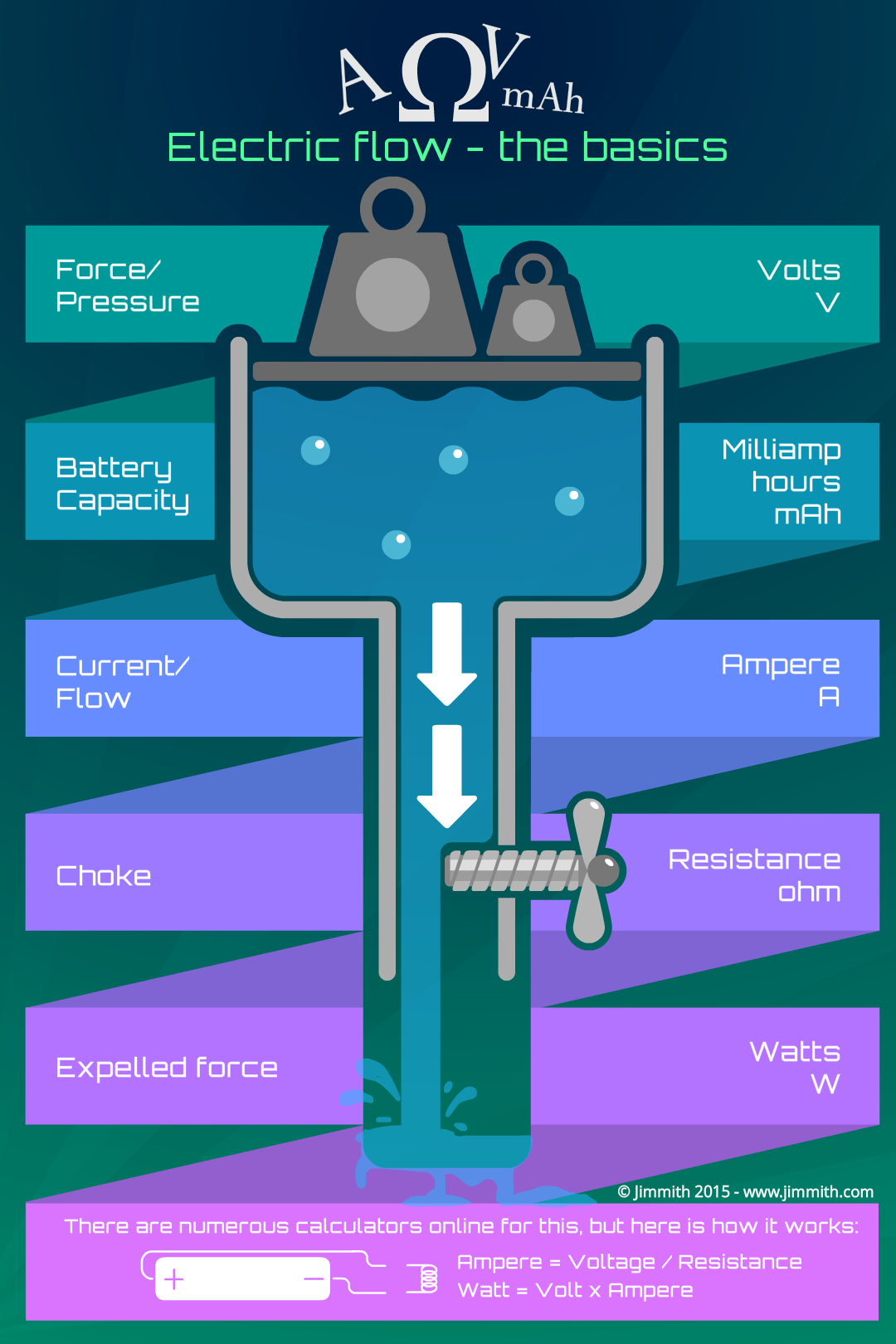

Electricity can be thought of as a pipe with water flowing through it. Water represents the electrons, and the pipe acts as a wire. In order to get water to flow through a pipe, there needs to be a difference in pressure between the ends of a pipe. Voltage is analogous to the pressure on either side of the pipe. There needs to be a difference in voltage in order to get the electrons to flow through the wire. This change in pressure is analogous to the change in voltage over the resistive element. In the pipe scenario, the amount of water flowing through the area of the pipe is the flow rate. In the wire, the electrons movement from one side to the other also has a flow rate. This rate is the current (measured in amperes or amps) flowing through the wire.

Now, let’s say that the pipe starts to get clogged. The pressure will stay the same, but the flow rate of the water will go down. Electrical resistance can be thought of as the “stuff” inside the pipe that is blocking the flow of water. The higher the electrical resistance, the less current that can flow at the same voltage. The major difference between the “stuff” that prevents the electricity from flowing is less of a physical blockage, but more of an intrinsic property of the material. Materials called conductors, like metals for example, have extremely low resistance, and are very willing to allow the electrons to flow within that material. Insulators, like rubber, have high values of resistance, and want to impede the flow of electrons in the material. Another distinction to make, is that in an electrical system a portion of the starting voltage will be used by each element that it is attached to, including the wires.

1.3 Importance of the Material That You Are Using

In most cases, we want a system to be as efficient as possible. Referring to the pipe with flowing water (above), it takes resources to keep the pressure of a system at a certain level. If there is blockage in the pipe, it takes more pressure to get the same flow rate than if the pipe was blockage free. In an electrical system, efficiency is paramount, and in many cases, we do not have control of the “pressure” (voltage). Typically, systems are specified to a given voltage. The main difference between the pipe and the wire is that when there is a high resistance, the system is consuming power. Some of the starting voltage was consumed by the resistance of the system; therefore, this energy is wasted. This voltage did not disappear though, it was converted to heat by the resistance of the system. Another reason that resistance is important is because high resistance cabling and paths can interfere with data that is being transmitted across the wires. In digital signals this can lead to low data speeds, high latency (delay), or signal loss all together. Analog data functions by measuring very precise voltages to correlate that signal to data, a high resistance changes the voltage that is seen at the measurement interface.

1.4 What is Resistance and How is it Measured

The electrical resistance of an object is an intrinsic material property, that describes how receptive an object is to the flow of electrons in the material. An object with a high value of resistance will not allow electrons to flow freely, while an object with low resistance, allows the electrons to pass by with ease.

An Ohmmeter is a device that can measure the resistance of a component. An Ohmmeter can be calibrated for a wide range of resistances. When measuring large resistances, a Mega-Ohmmeter will be used, and for small precise measurements, a Milli-Ohmmeter would be used. An Ohmmeter measures the resistance of an object by placing a known voltage on either side of the device and measure the current flowing though. These two values are all that are needed to infer the resistance. This inference can be made using Ohm’s Law. Ohm’s Law provides a relationship between the voltage over an element, the current flowing through it, and the resistance of the device. Following Ohms law, the voltage dropped over an element is the current flowing, multiplied by the resistance. V = I * R

1.5 What is Contact Resistance

Every component that is used in an electrical system has an intrinsic resistance, but when electrical components are joined together, there is an interface between two materials that can make the resistance greater than the sum of the two parts. This is because the electrons will have to leave one material, and then enter another material. This all boils down to how the surfaces are interfaced together. Two materials that are just pressed onto one another, for example, two wires that have been twisted together will have a higher resistance than two wires that are soldered or welded together.

1.6 Importance of Contact Resistance for a Device

There are so many reasons the contact resistance of a device is important. In devices like busbars, connectors, switches and relays, the contact resistance from the material interfaces can cause losses. These losses are realized as heat generated where the two materials interface.

The lower the contact resistance is, the more efficient a device is at transmitting electrons. A more efficient device means that the overall losses in the system are reduced, and heat generation is minimized. Power is not the only reason that electricity is used. Electrical signals are also used to transmit data. Signals differ from power transmission in several ways. In power transmission, the voltage is constant, and there is a significant amount of electron flow. In a signal, there is typically very little current, and the data is carried in the voltage level of the signal. The most basic type of signal is an analog signal. An analog signal transmits information in the voltage level that it carries. Most analog signals are the signals that one would get from a sensor. One example of an analog sensor is a thermocouple temperature probe. The voltage at the thermocouple interface can then be translated into a temperature. In order to get the most accurate results, it is best to minimize the voltage that is lost over the wires, and where the wires come into the measurement interface. In digital signals, like the widely used Ethernet, the data is correlated to the presence of a voltage above a set limit. In an Ethernet signal, there is a limit to how long the cable can be, which is determined by the resistance of the wire. When resistance is too high, systems/applications begin to have signal loss and consequently the Ethernet speed and latency suffers, causing application faults and downtime.

1.7 Contact Resistance and Slip Rings

One of the flaws of traditional brushed slip rings is in regards to their resistance. Since a traditional brushed slip ring relies on a carbon or metal brush rubbing against another contact plate, the contact resistance will be much different than a brushless interface such as a ROTOCON. The difference lies in how the two types of slip rings form the contact between the rotating and stationary sides. As mentioned previously, a traditional slip ring relies on a metal-on-metal, or graphite brush-on-metal contact. This interface is one of the sources of contact resistance in a traditional slip ring. This brush-on-metal contact is not perfect. The brush moves along the surface of the ring to create the contact. This contact is different in every place along the slip ring as it rotates, so the instantaneous resistance can vary greatly during the usage of a slip ring, even if the device is brand new.

The contact resistance of a slip ring can also vary over time. As a traditional slip ring is used, the brushes and rings wear away due to the continuous contact and rotation, just like a car tire wears away as it gets driven. As the brushes and rings wear away, they create dust and other particles that can coat surfaces and impede the flow of electrons. Eventually, the slip ring must receive maintenance. The brushes and rings may need to be replaced, and dust cleaned from the enclosure. This dust can cause a whole host of issues for the slip ring during use. When there is dust covering the surface of the contact interface, it creates extra layers that the electricity must go through to pass from the rotational side to the stationary side. These extra layers add interfaces that the electricity needs to flow through. In addition to the increased contact resistance. While this dust can add to resistance, this dust can also be a source of short circuits in a slip ring. This dust can form a film that can connect multiple contacts at elevated voltages, creating short circuits in the slip ring.

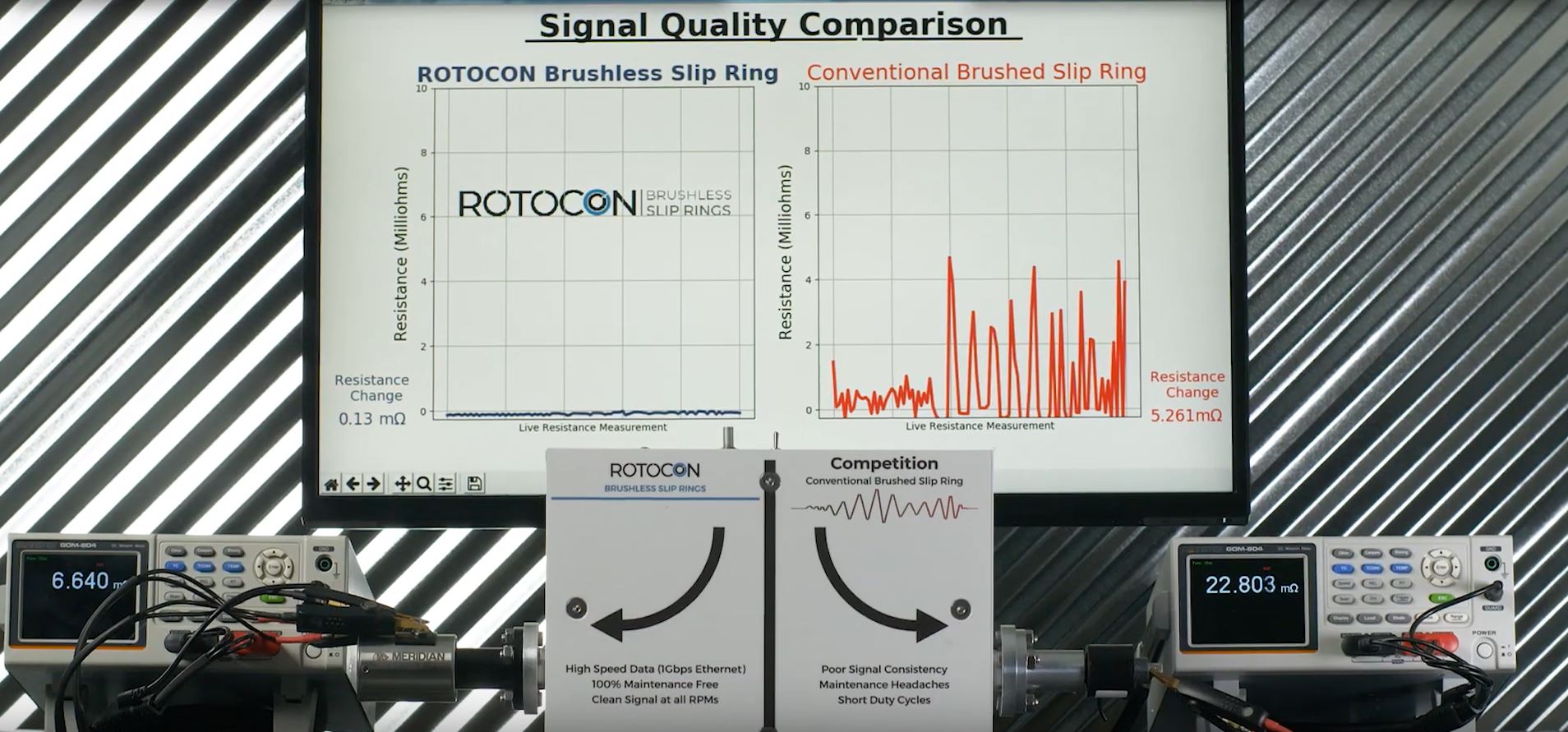

This video shows the change in resistance of two slip rings while rotating. On the left side, the ROTOCON’s resistance stays extremely low and stable, while the conventional brushed slip ring has a varying resistance much greater than that of the ROTOCON. The ROTOCON demonstrates approximately 1/20th of the resistance change when compared to a traditional brushed slip ring during rotation. A ROTOCON platform is unique because of its sealed contact system that is brushless and provides the cleanest electrical signal available in any rotary electrical contact solution, for both power and data signals, there is no measurable noise from these rotary electrical unions.

1.8 How Does This Effect My Application

In all applications, a certain amount of electrical noise and inefficiencies are acceptable. However, well-designed systems will perform better in maximizing output and lead to less system downtime. Choosing a high-quality slip ring is a way to ensure that a system performs at maximum ability.

Below are direct examples of the effects of choosing a traditional brushed slip ring, which is an inherently noisy device due to the constant changing of the resistance.

| Signal Type | Application | Effects of Contact Resistance |

|---|---|---|

| High Power | Welding, Heated Rollers, Plating, Motors, Windmills, Lighting | Varying current can result in unstable heating. This can cause hot spots on rollers, or inconsistent temperatures. In welding/plating applications, a consistent current is needed to maintain a quality process |

| Analog Voltage | Thermocouples, Pressure Transducers, Analog Voltage sensors | Incorrect temperature or pressure readings |

| Digital Signals | Ethernet, RS232, Encoders, Other communication protocols | Packet Loss, breakdown of communication protocols |

1.9 How is a ROTOCON Unique Compared to a Traditional Slip Ring

A ROTOCON brushless slip ring does not have the same faults that traditional brushed slip rings exhibit. A ROTOCON avoids this by getting rid of the electrically noisy metal on metal contact. This is done by utilizing a sealed fluid contact. This environmentally (hermetically) sealed fluid contact interface eliminates the contact resistance. In a ROTOCON, the contact is not created by pressing two conductors together, but instead transmitted through a mercury or other liquid metal film contact. This liquid metal film is bonded at the molecular level, held in an environmentally (hermetically) sealed oil chamber, and instead of the transition from a rotating to stationary source looking like a continuously changing contact resistance, the contact more directly emulates a wire than a traditional brushed slip ring.

Rotation in industrial environments causes many complicated problems, ROTOCON slip ring assemblies solve them. Where traditional metal-on-metal brushed slip ring contacts cause limitations within a process, maintenance headaches, short duty cycles, and lost time and money in production environments; ROTOCON brushless slip rings from Meridian Laboratory offer a maintenance-free, long-lasting alternative to conventional slip rings.