CASE STUDY

For US Military, ML6 High Friction Coatings Outperform All Others In The Field

Challenge

Meridian Laboratory was able to greatly diversify its product application and polyurethane ML6 usage after being selected by an American defense contractor to provide a solution for its next generation of an unmanned bomb diffusing robot. Challenged by the fact that the raw aluminum fingers were unable to provide enough grip to the items they were grabbing, Meridian Laboratory solved their dilemma through a high-precision, high friction, durable, custom profile. Since the addition of a thin layer of ML6 polyurethane, the robot is now able to accurately select delicate wires, grip slippery door handles, and puncture through glass with durable and high-friction pincers.

In designing the next generation of the bomb diffusing robot, the American based defense contractor had a problem. While plenty durable and lightweight, the aluminum pincer fingers they had designed weren’t able to do delicate tasks such as gripping wires, opening vehicle doors, or turning dials and other critical operations. After trying a variety of spray on coatings, molded rubbers, and adhesives they had run out of solutions that would provide high friction coatings with the durability they required.

Solution

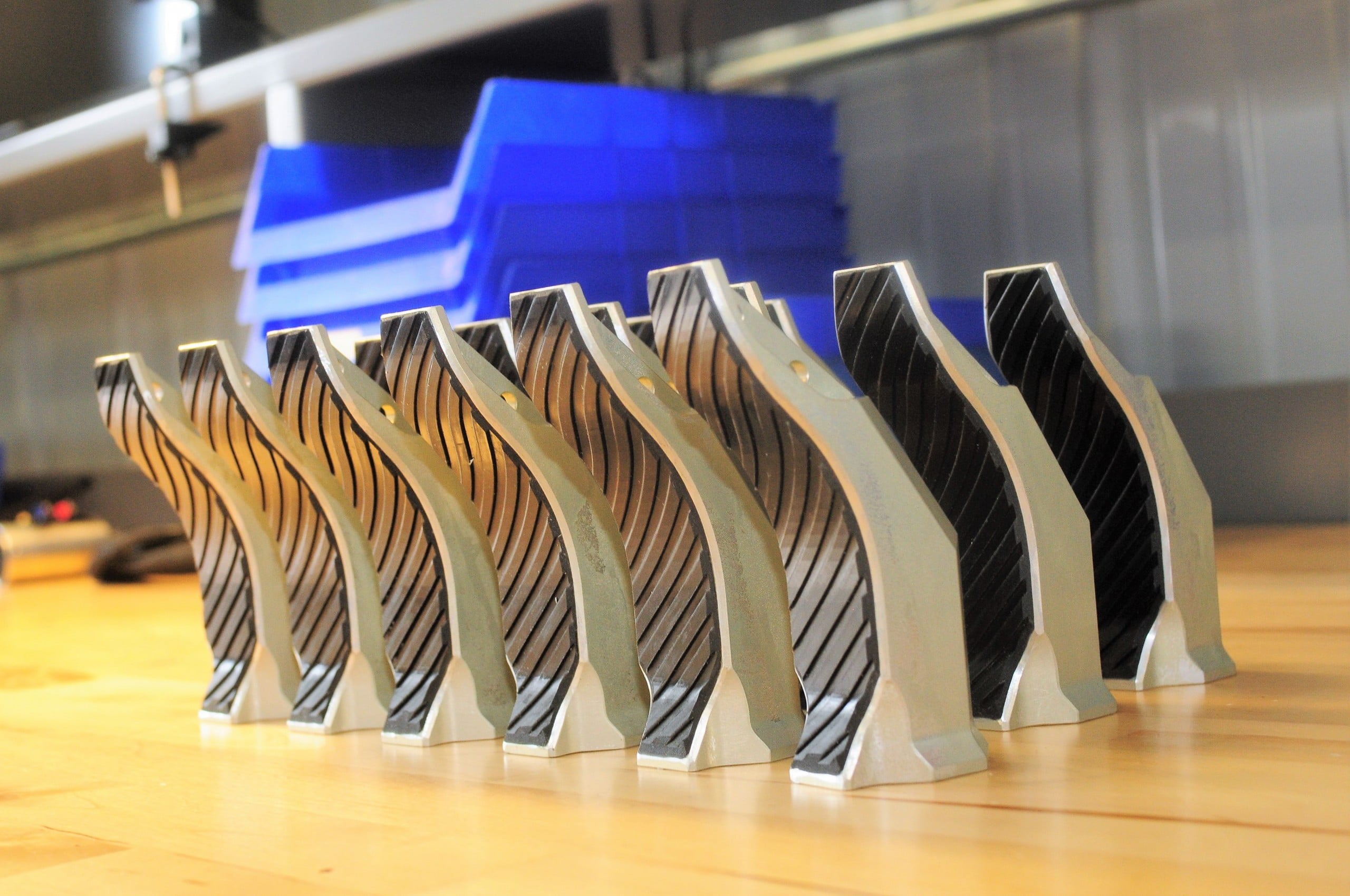

Working collaboratively with Meridian Laboratory’s engineers they were able to reengineer the pincer fingers to have a thin yet intricate profile of polyurethane ML6 applied to their billet aluminum fingers. Featuring complex curves on almost all of the surfaces, Meridian Laboratory developed customized tooling to meet the demanding and exact requirements of the drawings. Meridian Laboratory was able to begin by coating SLA and SLS 3D printed prototype parts. Once a final design was completed, Meridian Laboratory was able to deliver numerous sets of polyurethane robotic fingers, all to exacting tolerances of +/-0.001” or better. The end result was a dramatically better performing robotic pincer, providing excellent gripping capability while remaining durable and rugged for over a year of harsh testing.

Key Statistics

- Polyurethane ML6 was applied to complex curved fingers with an intricate pattern

- Drastically improved gripping capability of pincer fingers on small and delicate objects

- High friction polyurethane ML6 able to endure harsh environments and usage