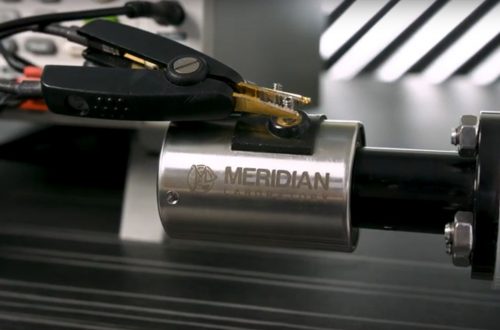

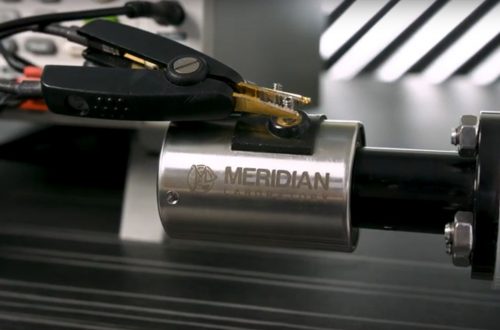

Signal Quality Demonstration: Conventional Slip Ring vs. ROTOCON

Slip Ring Signal Quality Demonstration Since 1963 Meridian Laboratory has manufactured brushless…

For more information on ROTOCON® Slip Ring Assemblies, visit our FAQs.

View FAQsHAVE QUESTIONS? WE’RE HERE TO HELP.

A ROTOCON is a proprietary and exclusive design of slip ring, engineered and manufactured by Meridian Laboratory to provide unparalleled performance and flexibility for all rotary electrical connection needs. Unlike conventional brushed slip rings which utilize metal-on-metal contacts and are limited by RPM, electrically noisy, and require adjustment and maintenance for proper operation – all ROTOCONs are brushless, functioning through a molecularly bonded viscous metal film which remains unaffected by speed, provides clean and noise-free electrical signals, and requires zero maintenance.

Due in part to the Meridian Laboratory exclusive brushless design, which provides the engineering core all ROTOCONs are built with, the contact resistance, and thus signal quality, is significantly better than traditional brushed slip rings. Regardless of whether you are transferring low voltage communication signals, high voltage measurement signals, or a combination of both – you can expect perfect signal integrity regardless of RPM, total revolutions, or environmental factors.

Yes! ROTOCONs are an excellent solution for Ethernet and other communication protocols, being unaffected by data speed, RPM, vibration, and other factors which typically lead to faults and packet loss with conventional, brushed slip rings. Meridian Laboratory has a wide variety of off-the-shelf solutions built to handle 10/100/1000Mbps Ethernet and other communication protocols, along with power/control wires within the same assemblies.

Yes! Meridian Laboratory ROTOCONs are able to accept virtually any thermocouple type and can be designed to integrate thermocouple wire directly into the ROTOCON units, combined with power, signal, communication, and other wires in the same assembly.

Many ROTOCON rotary connectors built 30+ years ago are still in use today, due in part to their exclusive and unique brushless and maintenance-free design. Contrary to conventional brushed slip rings which rely on metal-on-metal contacts, ROTOCONs do not wear out over time. ROTOCON rotary electrical connectors are built for continuous use, industrial and production level operations and applications. They are rated for 100% duty cycle and do not require maintenance during the lifespan of their existence.

ROTOCONs are available in configurations ranging from single contact up to 100 channels.

Nearly all units are rated to a minimum of 600V AC/DC, however in some instances they may be less and we encourage you to check with us if you have any questions of your specific model. Otherwise, we offer standard high voltage designs (MXV-Series) rated up to 1500V, 2500V, 3500V but can build custom multi-channel solutions rated up to 5,000V. Single contact versions (MC-Series) are unaffected by the voltage passing through them, and can handle a theoretically infinite voltage.

Given their unique design, ROTOCON rotary electrical connectors are able to operate at much higher RPM’s than conventional, brushed slip rings. The maximum RPM of any ROTOCON is dependent on the series (configuration type) and duration of speed, environmental conditions, and other factors. For speeds ranging above 3,000 RPM – please see our full series of MM-Series, Miniature High-Speed ROTOCONs. For application speeds ranging up to 40,000 RPM – please see our UHS-Series, Ultra-High Speed ROTOCONs. For operation questions above the rated max RPM – contact Meridian Laboratory.

Yes! Meridian Laboratory has a wide variety of through-hole (also called through-bore) ROTOCON rotary electrical connectors available to mount on a shaft, up to 4.00” in diameter. Click here for more information on our Through-Hole, MXT-Series.

Yes! Meridian Laboratory has a wide array of standard, Ethernet/communication ready, power, signal, and thermocouple ROTOCONs in stock. In addition to standard models, we excel in providing custom and optimized solutions in a quick and timely fashion, without engineering or development fees.

Yes! Meridian Laboratory has over 5,000 standard models, any of which can be built to meet your needs (and many of which are kept in stock). We also have the ability to deliver specialized and custom slip ring solutions in a matter of weeks time, in-house – or provide value added products and services such as rotary unions, fiber optic rotary joints, encoders, and other engineering and design related services. Click here for more information on customized solutions.

Yes! Meridian Laboratory offers rotary unions to provide combined slip ring and single and multi-passage rotary union combinations. Meridian Laboratory has the expertise and product knowledge to serve as your single source solutions provider for all rotary electrical and fluid needs. Click here for more information on our rotary union combinations.

Yes! Meridian Laboratory now offers fiber optic rotary joints both single and multi-channel in design. Meridian Laboratory offers integration of ROTOCON and fiber optic rotary joints with product knowledge and support to serve as your single source solutions provider for rotary electrical and optical needs. Click here for more information on our Slip Ring & FORJ integrations.

The only effect RPM has to a ROTOCON is the temperature rise which the rotating components cause internally, otherwise none! ROTOCONs remain unaffected in signal quality, communication packet transfer, or its ability to conduct and transmit electrical signals by varying or increased RPM. ROTOCONs greatly outperform conventional slip rings which suffer from brush wear, carbon build up, brush bounce, and arcing with its unique brushless and maintenance-free design.

No, at this time Meridian Laboratory does not offer flatter, ‘pancake style’ solutions. This style of design is more prohibitive in maximum RPM and maximum amount of contacts, which is one of the many advantages which Meridian Laboratory ROTOCONs have over conventional slip rings.

ROTOCONs are offered in a wide variety of different configurations and terminations options to best fit your needs and various levels of sealing requirements of your application. A standard ROTOCON is environmentally sealed (internally) but typically features flying leads and/or ring terminals to make electrical terminations with. The body/internals of a standard ROTOCON are splashproof, however there still exists opportunity for external shorting to occur (via liquid paths) if ring terminals are exposed and present.

One way to add increased environmental sealing protection to the unit is by opting for a MIL-spec connector, or flying leads to be molded into the unit and making your terminations elsewhere in a sealed area of the machine.

Lastly, for subsea applications or units which will be continuously exposed to wet, humid, or dusty environments we offer an additional internal sealing mechanism (see our Harsh Environmental, MXO Series) which features additional sealing mechanisms internally to further prevent water, dust, or other particles from entering the unit. It is generally recommended these units are built with potted leads or subsea connectors.

Yes, select ROTOCON models are available as RoHS and CE compliant. The revolutionary ERG Series of electrical rotary grounds provide a consistent, maintenance-free, rotating electrical contact and connection unaffected by instantaneous RPM (for high-speed applications) or total number of revolutions. Current models are rated at 400A and 800A.

Model Number/Part Number: ERG-400-01-R, ERG-400-02-R, ERG-400-11-R, ERG-400-21-R, ERG-400-

22-R, ERG-800-01-R, ERG-800-02-R, ERG-800-11-R, ERG-800-21-R, ERG-800-22-R, ERG-800-31-R

Either portion of the ROTOCON can be the stationary or rotary part of the application, without affecting quality, longevity, or performance of the ROTOCON rotary electrical connector. It is absolutely critical however to allow flexibility between the rotary and stationary portion of the ROTOCON connector. The body or the shaft can be fixed, consequently allowing the opposite portion to move freely. Failure to do this will drastically shorten the lifetime of the ROTOCON.

Contact Meridian Laboratory for direct sales and technical support, or for the names and locations of authorized distributors.

Meridian Laboratory

2415 Pleasant View Rd.

Middleton, WI 53562

Phone (608) 836-7571

T. Free (800) 837-6010

info@meridianlab.com

Meridian Laboratory

Meridian Laboratory2415 Pleasant View Road, Middleton

5.0 47 reviews

Slip Ring Signal Quality Demonstration Since 1963 Meridian Laboratory has manufactured brushless…

Challenge An American based manufacturer of helicopter blades approached Meridian Laboratory with…

Rotocon Brushless Slip Rings vs Gold Plated Contacts Many manufacturers of conventional…

A worldwide designer and manufacturer of bottle filling and capping systems has…