Unlike conventional brushed slip rings which rely on metal on metal contacts and are limited by RPM, electrically noisy, and require adjustment and maintenance for proper operation – all ROTOCONs are brushless, functioning through a molecularly bonded viscous metal film which remains unaffected by speed, provides clean and noise-free electrical signals, and requires zero maintenance.

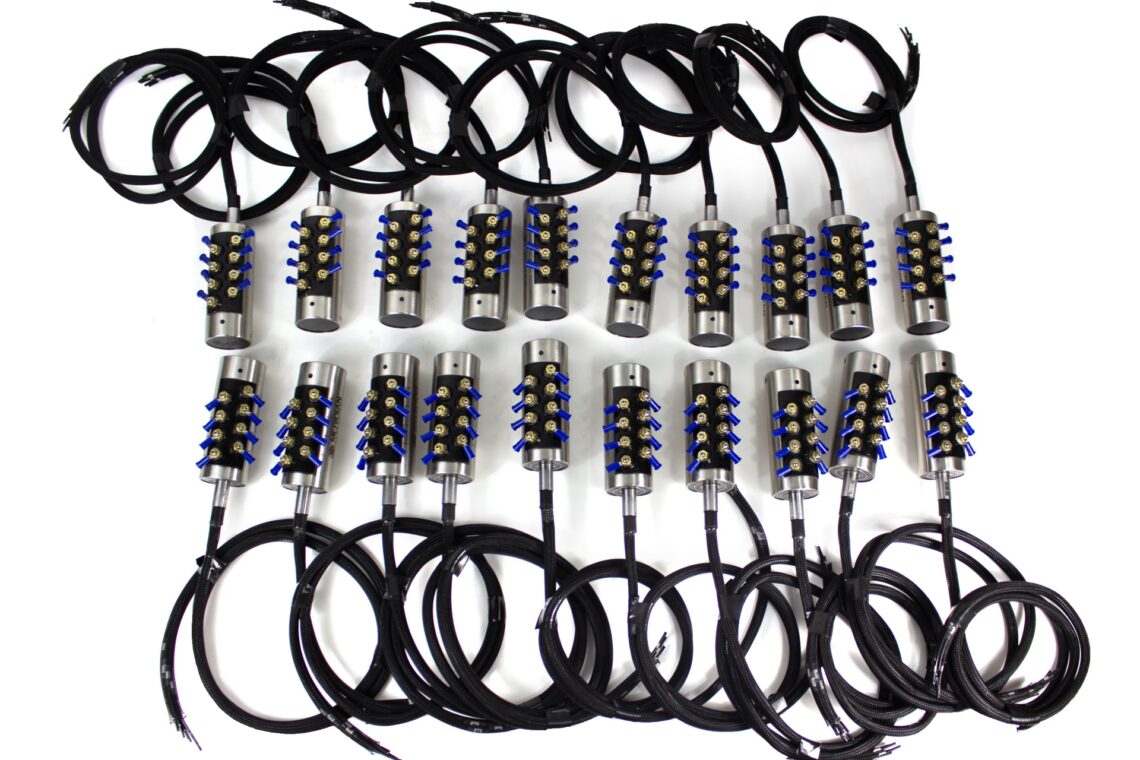

For power transmission, this means zero internal arcing and premature wear – allowing for increased reliability and longevity. ROTOCON rotary electrical connectors oftentimes outlast conventional brushed slip rings between 5 and 25x without the need for maintenance, adjustment, or downtime.

For signal transmission – this means ROTOCONs are guaranteed to transfer 100Mbps and 1Gbps Ethernet (or equivalent communication protocols) without the loss of packets, occurrence of bit errors, and other data problems that routinely occur with traditional, brushed slip rings.

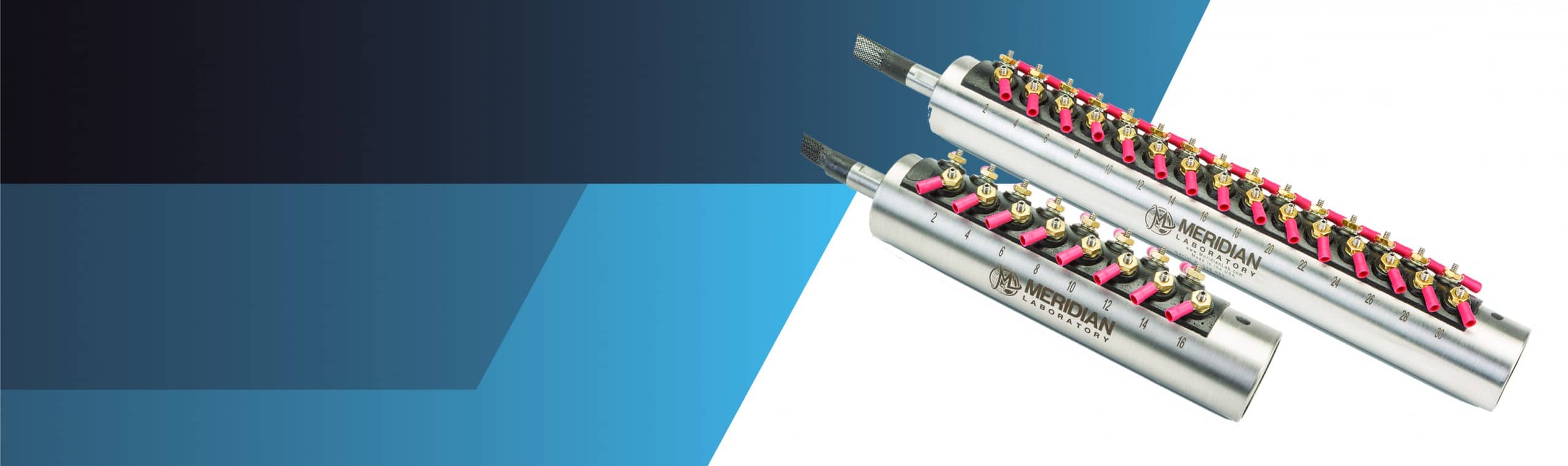

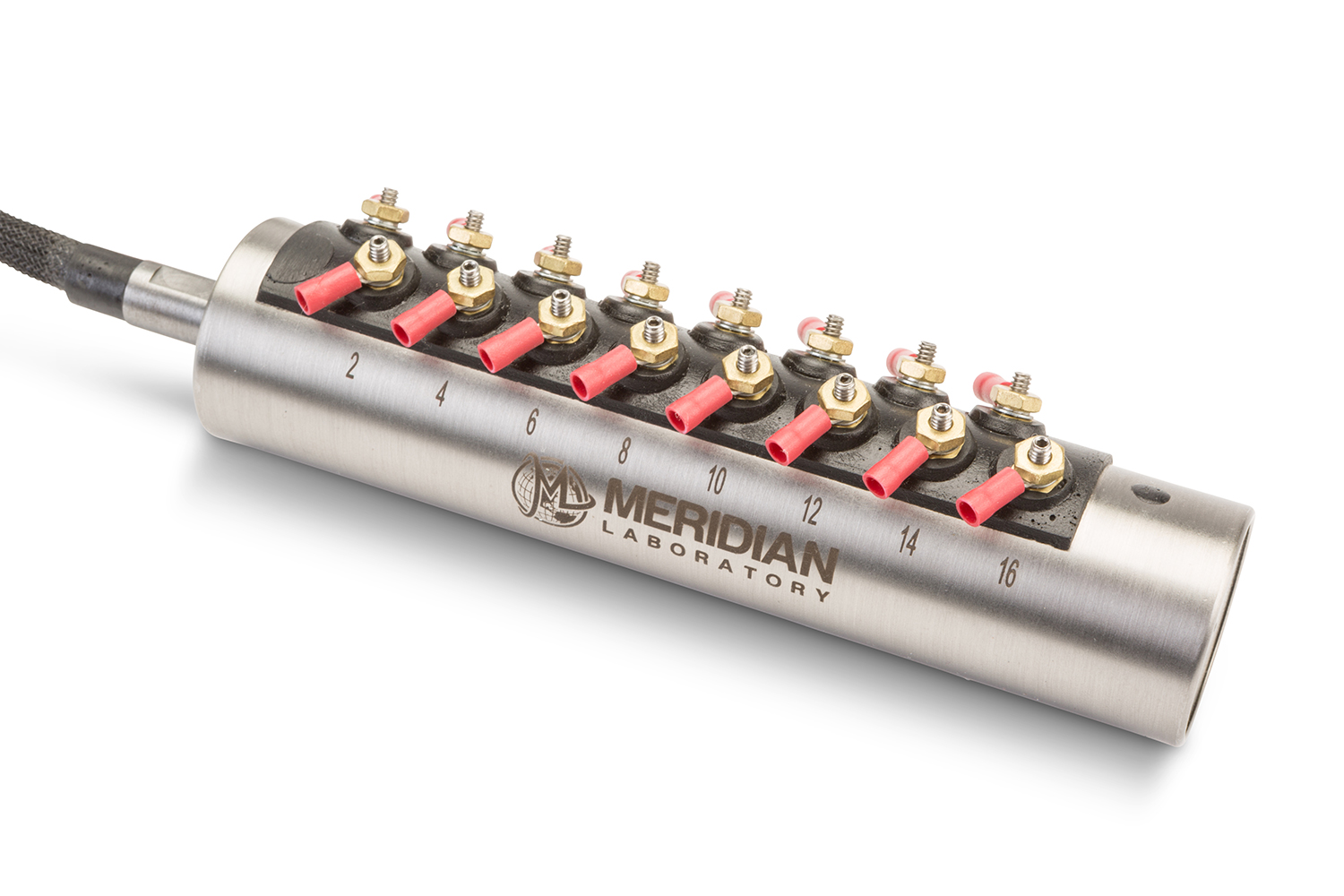

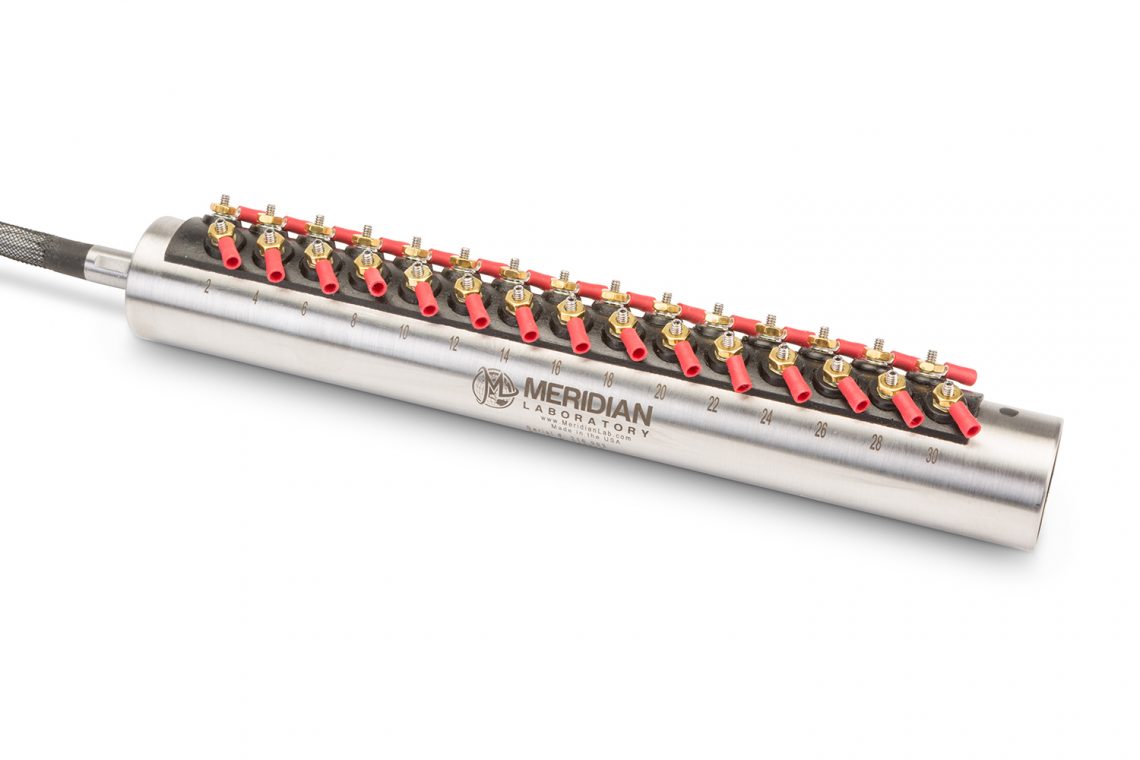

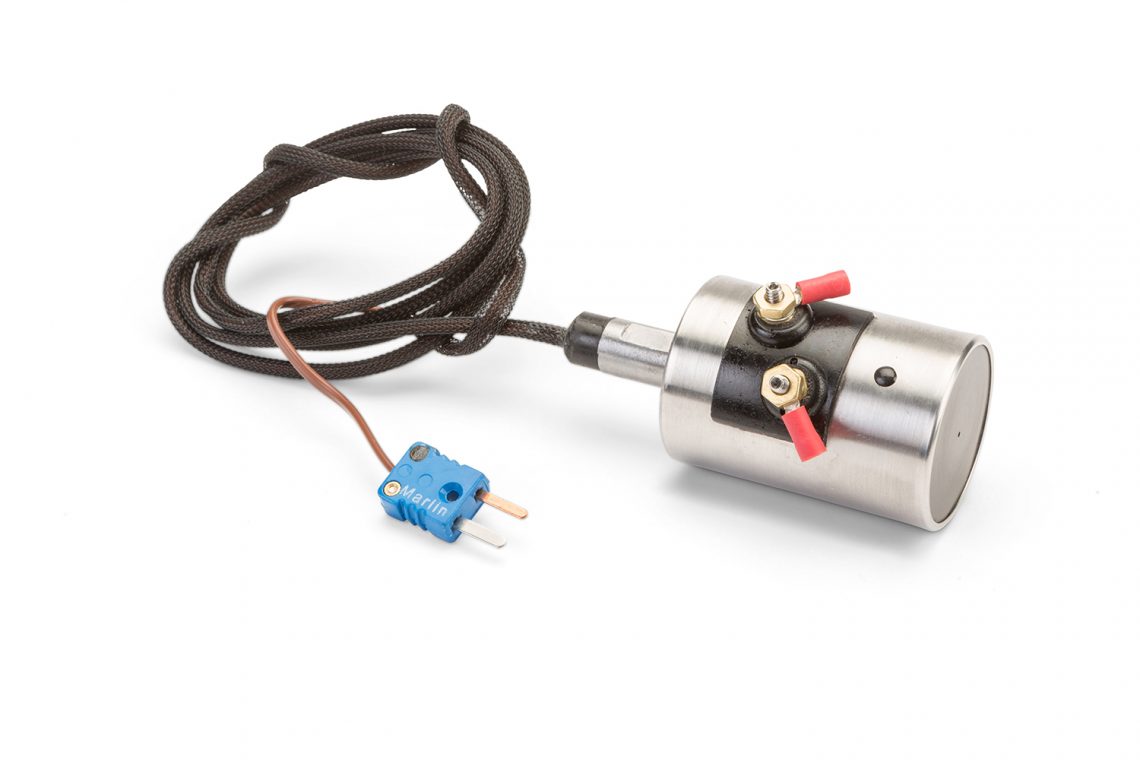

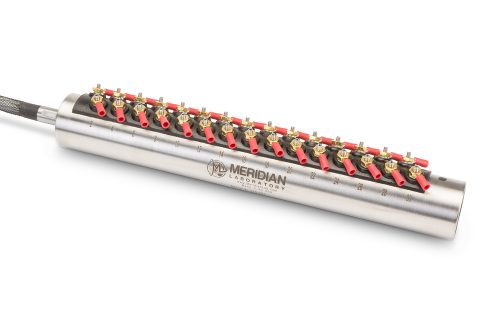

The ROTOCON M-Series is designed for continuous use, industrial applications and is routinely used in a variety of packaging, test & measurement, food processing, strain & torque measurement, oceanographic instrumentation, and many other manufacturing & production related processes.

For size constricted applications, see our full line of Miniature, MM-Series rotary electrical connectors.

Video: Conventional Slip Ring vs. ROTOCON Signal Quality Demonstration

The ROTOCON platform utilizes a sealed contact system that is brushless, 100% maintenance-free, and provides the cleanest electrical signal available in any rotary electrical contact solution, for both power and data signals, you can count on no measurable change of resistance (noise) from a ROTOCON rotary electrical union.

| RPM | Model dependent, see model specifications |

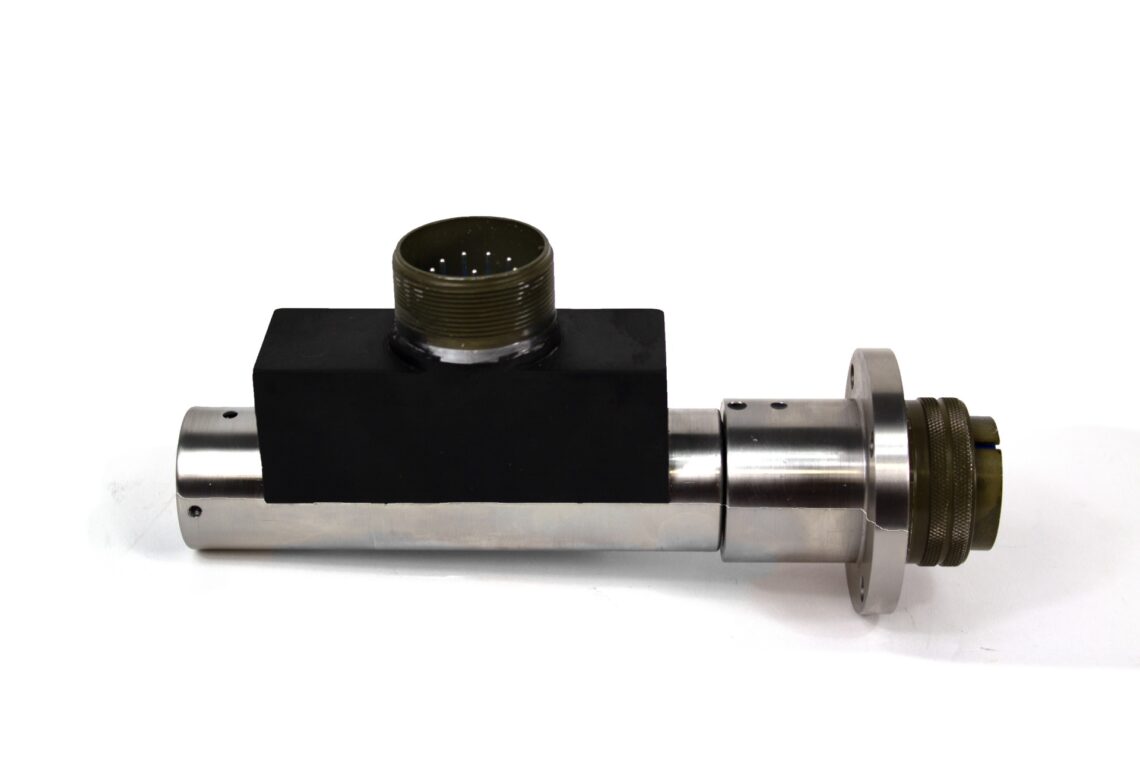

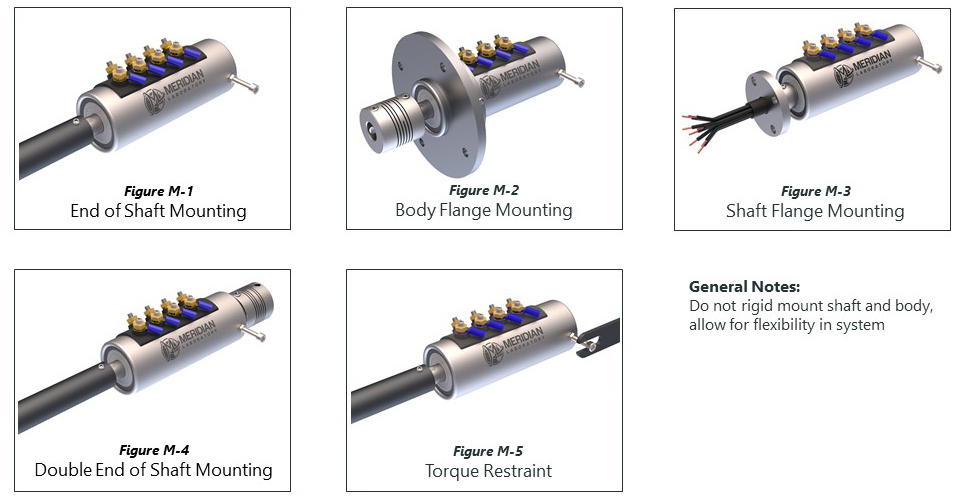

| MOUNTING | End of shaft or flange (Click here for installation and best practices video.) |

| HOUSING MATERIAL | 304 Stainless steel |

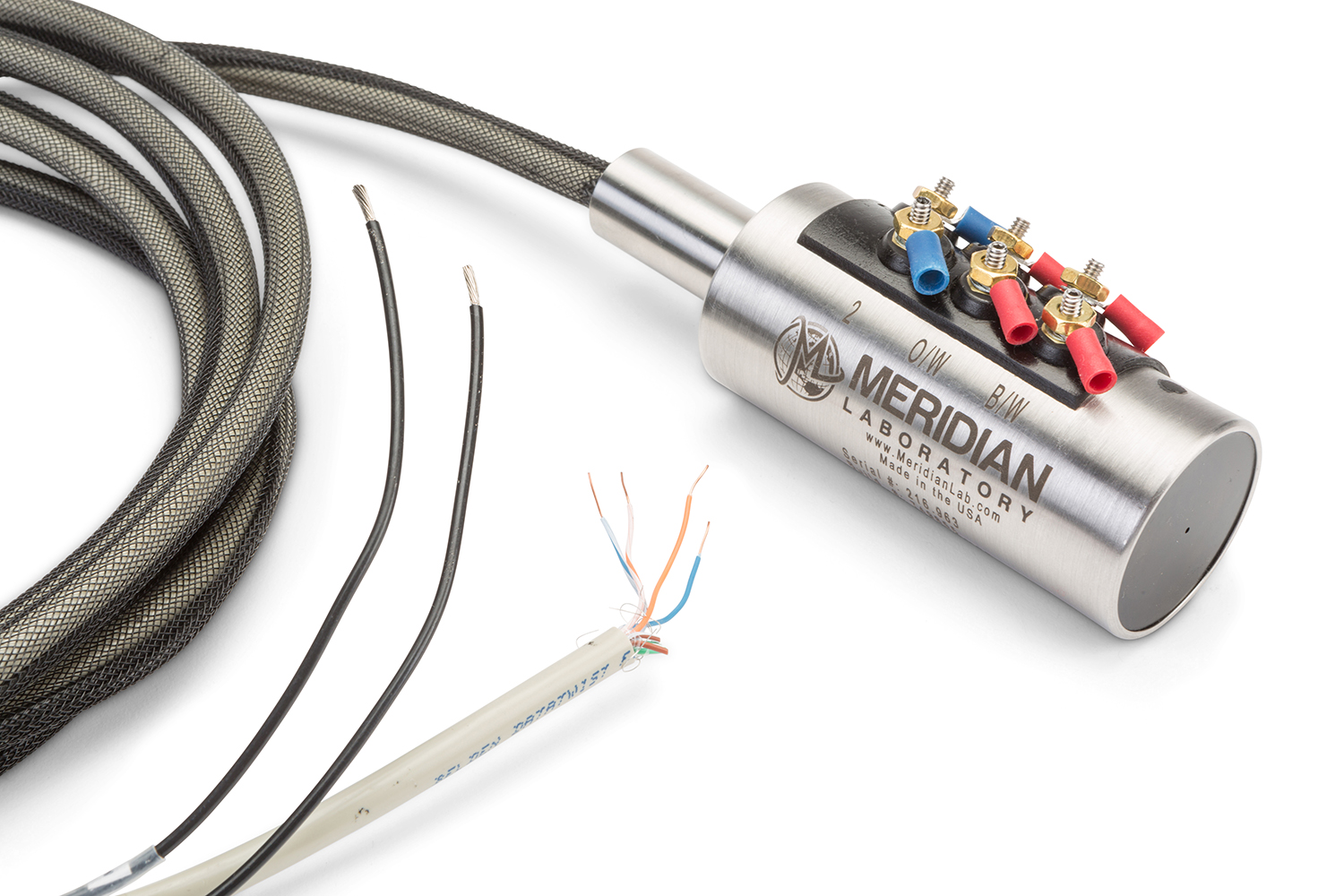

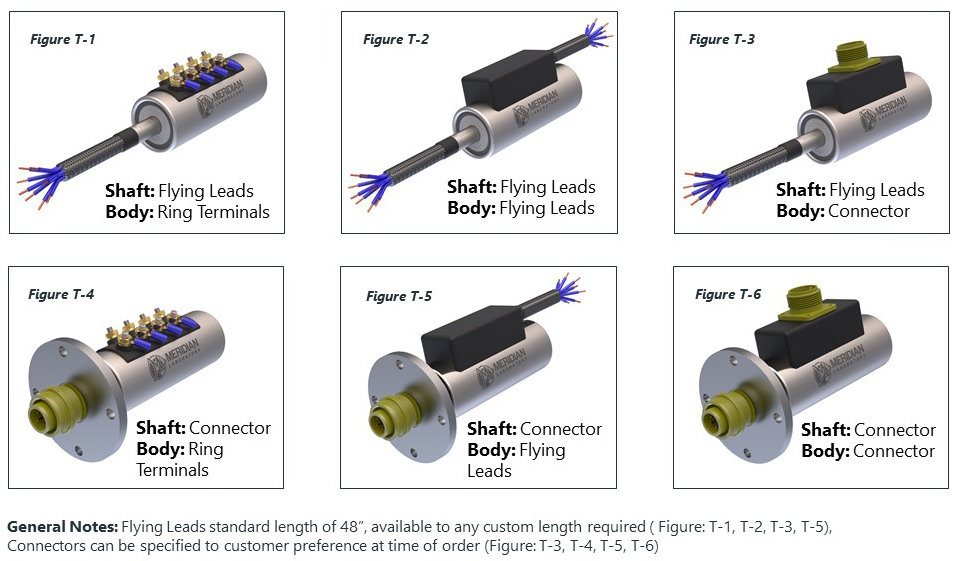

| TERMINATIONS | Ring terminals, flying leads, MIL-spec or other connectors |

| OPERATION | Can be operated in any direction or orientation |

| MAINTENANCE | Features permanently lubricated bearings, brush-free design requires no user maintenance |

| VOLTAGE | Standard: Up to 600V AC/DC, Optional: Up to 3,500V AC/DC |

| MINIMUM INSULATION RESISTANCE | >500MΩ @ 1kVDC |

| AMPERAGE | Model dependent, up to 35A/channel (channels can be bridged in parallel, for higher capacity) |

| FREQUENCY | Up to 1GHz (Model and application dependent) |

| DATA & SIGNAL TRANSMISSION | Ethernet (10/100/1000Mbps), Etherlink, LAPPNET, Profinet, Profibus, ControlNet, DeviceNet, CAN-Bus, RS485, RS432, RS422, USB (1.0/2.0), Modbus, EtherCAT, CC-Link, coax, thermocouple (all types) and all other major communication protocols (With an appropriate number of circuits and cables) |

| STATIONARY CONTACT RESISTANCE | <0.1mΩ |

| ROTATING CONTACT RESISTANCE (0-MAX RPM) | Same as stationary contact resistance (<0.1mΩ) |

| ELECTRICAL NOISE | <0.01uV |

| NOTES | Intrinsically immune to internal arcing, designed for continuous operation |

| AMBIENT TEMPERATURE | Not to exceed 160˚F (70˚C) |

| IP RATING | Available up to IP67 |

| RPM | Up to 15,000 RPM |

| MOUNTING | Through-hole, end of shaft, or flange mount available |

| HOUSING | 6061 Aluminum or 304 Stainless steel |

| PASSAGES | Up to 20 Passages |

| PRESSURE | Up to 23,000 PSI - speed and media dependent |

| TEMPERATURE | -321F to 900F, depending on options |

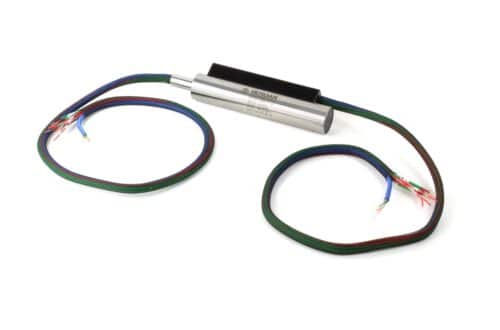

| FIBER TYPES | Single-mode E9/125μm Multi-mode G50/125 μm Multi-mode G62.5/125 μm *Fiber protection available |

| CHANNELS | Standard: 1, 2, 3-20 Channels Custom: Up to 81 Channels |

| CONNECTOR TYPE | SC, LC, FC, ST, LSA, Molex/LC, LuxCis |

| POLISH | UPC, APC, PC |

| DIGITAL DATA TRANSMISSION | Up to 40Gbits/s per channel |

| RPM | Up to 3,000 RPM (Model specific) |

| TEMPERATURE | -40F to 185F |