Durometer Information, Polyurethane Durometer

What Is Polyurethane Durometer?

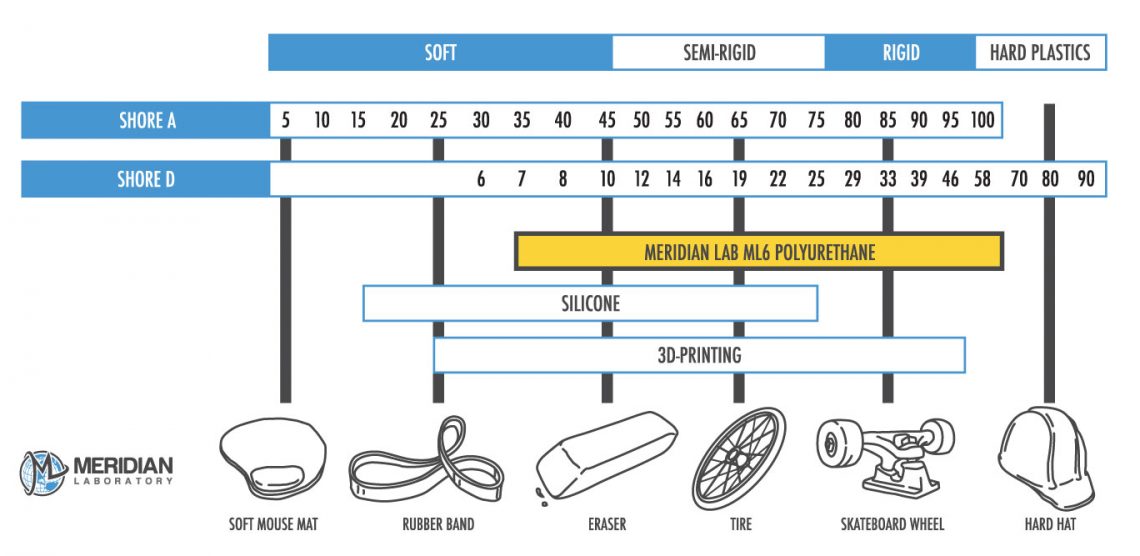

The hardness of any soft material such as rubber, plastic, polyurethane, or non-metallic material is measured in durometer, which is similar to how steel is measured on the Rockwell scale. There are various methods with which to measure durometer to encompass the wide range of hardness which these materials come in.

The Shore A hardness scale is the most commonly used scale in production and manufacturing applications due to its wide range and versatility of uses within the scale. The Shore A scale can range from parts that are flexible and soft in nature (0-40A), to semi-flexible and medium-hard (50-80A), to very hard and rigid (90-100A). Meridian Laboratory operates primarily in the Shore A scale and commonly offers 40A, 55A, 70A, 80A, 90A in durometer choices, but is not limited to these durometers.

The hardest scale in plastic, rubber, and polyurethane measurement is Shore D. Shore D can most commonly be associated with hard rubbers and plastics, but also some polyurethanes. Meridian Laboratory offers precision polyurethane parts in the Shore D scale to 75D.

How Do You Measure Durometer?

Durometer is measured using a durometer gage, which comes in a variety of configurations depending on sensitivity, accuracy, and read-out options. A durometer gage operates on the principle of a point or indentor pressing against a surface in a flat manner, with a spring or sensor translating this into a read out, in a digital or analog form. Based on the Shore scale being measured, it is recommended that an indentor is the appropriate shape and size to avoid reading errors.

It is recommended that thicknesses under ¼” are not measured in this fashion as it is typically too thin of a material to measure accurately. In these cases, it is recommended the material is layered in order to get a proper durometer measurement. It is important that if there is a core to which the material is bonded to, so that this does not improperly affect the reading. If you are unsure of the durometer of a certain part, Meridian Laboratory can measure the part’s durometer and match, or provide design improvement ideas depending on your product, application, and goals.

Why Is Durometer Important?

Choosing the right durometer for your part is important for a variety of reasons, particularly in applications which the parts being handled could be damaged if too hard of a durometer is chosen. In drive applications, where friction is oftentimes most important, it is important to select a durometer that adequately drives the parts it comes in contact with, without being so soft that the polyurethane deforms over long periods of time. However, the harder a part is, the less friction it provides, therefore selecting a durometer that best meets your specific application is important. From its 55 years of polyurethane experience, Meridian Laboratory is able to provide engineering-driven recommendations and suggestions.

Why Performance Matters

While it’s easy to think “it’s just a roller”, it’s even easier to lose sight of how much you ask of your rollers and wheels, day in and day out. Keeping your operations running with a minimum of downtime for machine repairs, feed jams, tuning of encoder wheels, or other time wasters (and money costers) means upgrading to superior components for your application. If you expect and demand that your equipment do more, ML6 offers a proven upgrade you’ll notice immediately.

What Makes Meridian Laboratory ML6 Different?

While Shore scales and durometers are universal across the world, Meridian Laboratory ML6 is unlike any other polyurethane material available on the market. It is particularly unique due to its high friction and low-wear characteristics. Traditional polyurethane manufacturing involves grinding the polyurethane, and most manufacturers will recommend and require a very low durometer in order to meet the friction requirements of the application. The tradeoff for this is the lifespan of the roller. Meridian Laboratory does not grind any of its rollers and relies on a sealed, high-friction drive surface. With its superior surface finish and friction quality, Meridian Laboratory ML6 can often provide the same friction qualities of lower durometer material, with the longevity and wearability of a higher durometer.

Browse a collection of unique projects from the ML6 Product Gallery page.