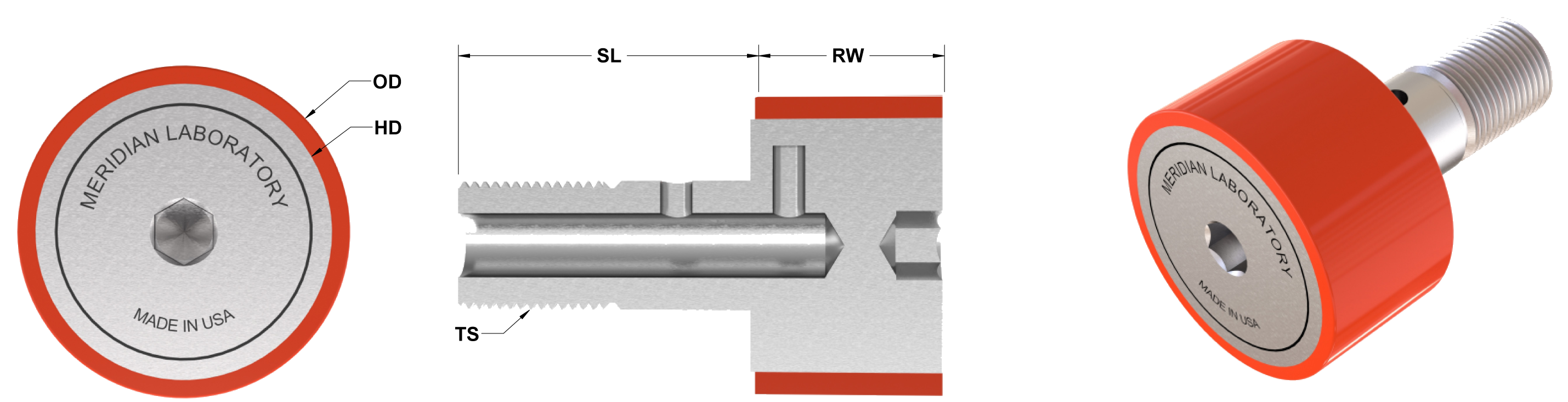

ML6 track rollers feature a flat rolling surface that is quiet, precise, and provides better traction and abrasion resistance than nylon or other types of covered rollers. The bond between Meridian Laboratory’s ML6 polyurethane and the cam follower is stronger than the polyurethane material itself – guaranteeing excellent longevity!

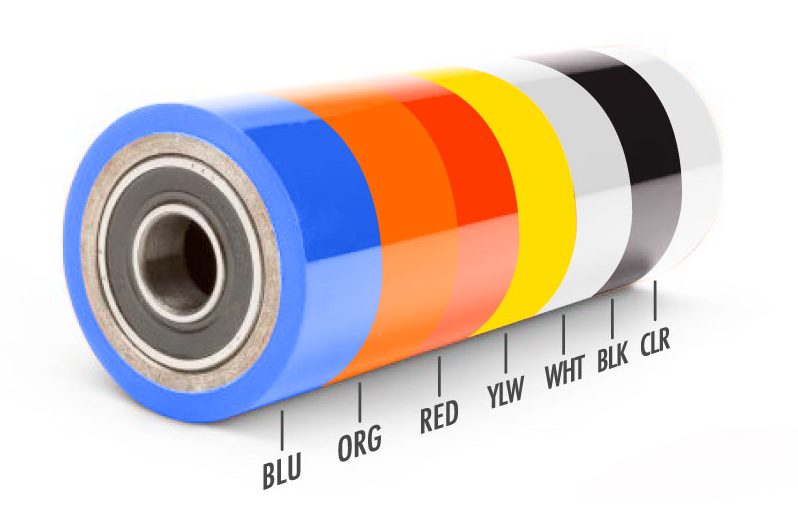

Polyurethane coated cam followers are available in a variety of sizes, colors, and durometers to meet any of your most demanding requirements. Yoke rollers, featuring a thru-bore rather than a threaded shaft are available in the same sizes as our studded cam followers. Click here to shop online.

Why Precision Matters

While it’s easy to think “it’s just a roller”, it’s even easier to lose sight of how much you ask of your rollers and wheels, day in and day out. Keeping your operations running with a minimum of downtime for machine repairs, feed jams, tuning of encoder wheels, or other time wasters (and money costers) means upgrading to superior components for your application. If you expect and demand that your equipment do more, ML6 offers a proven upgrade you’ll notice immediately.

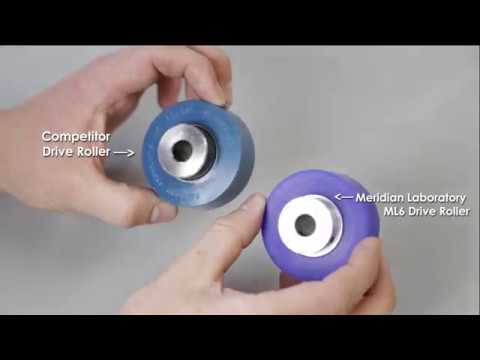

Video: The Importance of Total Indicated Runout When Selecting Polyurethane Rollers

In this short video above, discover one (of many) reasons a more durable, precision roller can have a huge impact on your manufacturing environment.

Custom colors available on request

| ML6-40A | ML6-55A | ML6-70A | ML6-80A | ML6-90A | ML6-60D | |

|---|---|---|---|---|---|---|

| Hardness (+/- 5) | 40A | 55A | 70A | 80A | 90A | 60D |

| Ultimate Elongation (%) | 640 | 540 | 540 | 640 | 500 | 300 |

| Ultimate Tensile (PSI) | 3200 | 5300 | 5600 | 6900 | 6200 | 6400 |

| Tear Strength, pli Die "C" | 150 | 244 | 332 | 421 | 568 | 620 |

| Split | 19 | 51 | 92 | 175 | 134 | 125 |

| Compression Modulus (Young's Modulus) | 380 | 830 | 1660 | 1990 | 6460 | 16200 |

| Compression Set (% 22 Hrs. @ 158ºF) | 0 | 1 | 7 | 16 | 18 | 30 |

| Bashore Rebound (%) | 50 | 41 | 37 | 31 | 35 | 52 |

| Abrasion Loss, mm | 200 | 224 | 159 | 94 | 101 | 115 |

For more information, contact Meridian Laboratory