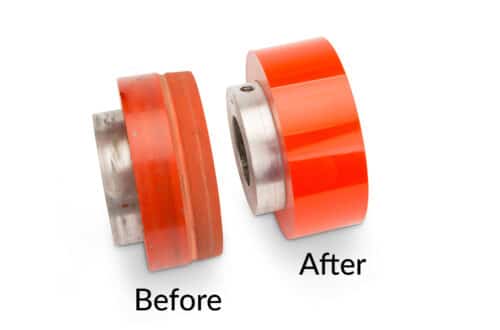

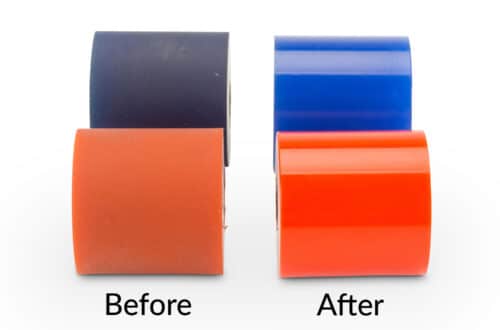

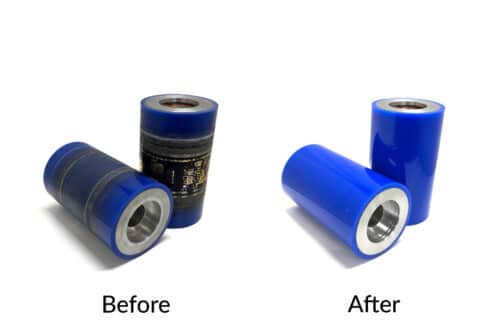

Upon receipt of rollers, shafts, and other parts for refurbishment, Meridian Laboratory will analyze the parts as follows:

- Measure existing coating for dimensions or obtain desired measurements and sizes.

- Measure the durometer of existing coatings or obtain desired durometer.

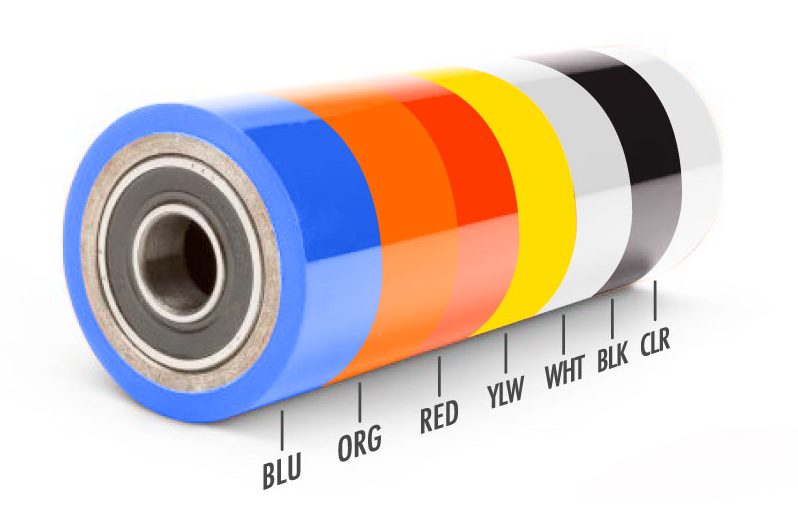

- Confirm with customer desired dimensions, colors, and durometers.

- Measure cores, shafts, and other parts for tolerances.

- Repair or replace any cores that are out of tolerance.

- Bond new Meridian Laboratory polyurethane ML6 to specifications.

- Measure and ensure recovered tolerances match desired specifications.

If desired, Meridian Laboratory’s team will also make recommendations on changes to rollers, shafts, and other parts that need recovering. Whether the desired outcome is cost reduction, increased longevity, or higher friction the Meridian Laboratory’s team can assist you in achieving your goals. Custom sizes and profiles are available very affordably, with turnaround times in as little as 5 days.

Custom colors available on request

| ML6-40A | ML6-55A | ML6-70A | ML6-80A | ML6-90A | ML6-60D | |

|---|---|---|---|---|---|---|

| Hardness (+/- 5) | 40A | 55A | 70A | 80A | 90A | 60D |

| Ultimate Elongation (%) | 640 | 540 | 540 | 640 | 500 | 300 |

| Ultimate Tensile (PSI) | 3200 | 5300 | 5600 | 6900 | 6200 | 6400 |

| Tear Strength, pli Die "C" | 150 | 244 | 332 | 421 | 568 | 620 |

| Split | 19 | 51 | 92 | 175 | 134 | 125 |

| Compression Modulus (Young's Modulus) | 380 | 830 | 1660 | 1990 | 6460 | 16200 |

| Compression Set (% 22 Hrs. @ 158ºF) | 0 | 1 | 7 | 16 | 18 | 30 |

| Bashore Rebound (%) | 50 | 41 | 37 | 31 | 35 | 52 |

| Abrasion Loss, mm | 200 | 224 | 159 | 94 | 101 | 115 |

For more information, contact Meridian Laboratory