CASE STUDY

ML6 Drastically Improves Maintenance and Reduces Replacement Costs and Lead Time

Challenge

A thriving, local business with a 50-year history in commercial printing and converting was able to drastically reduce the cost and lead time by using the roller recovery services provided by Meridian Laboratory. After nearly twenty years of reordering expensive replacement rubber rollers for their European based printing and converting equipment, they were able to quickly and cost effectively recover worn out rollers with precision polyurethane ML6 by Meridian Laboratory.

A commercial printing and converting house was plagued by routinely having to purchase new replacement rollers for their equipment. The majority of their equipment originated from Europe and replacement rubber rollers were expensive and took weeks to get. The aluminum and stainless steel cores were in perfect condition but the rubber coating wore quickly and with unpredictable longevity. Maintenance and repair costs associated with replacing worn out rubber rollers cut into profitability and made downtime unpredictable and difficult to plan.

Solution

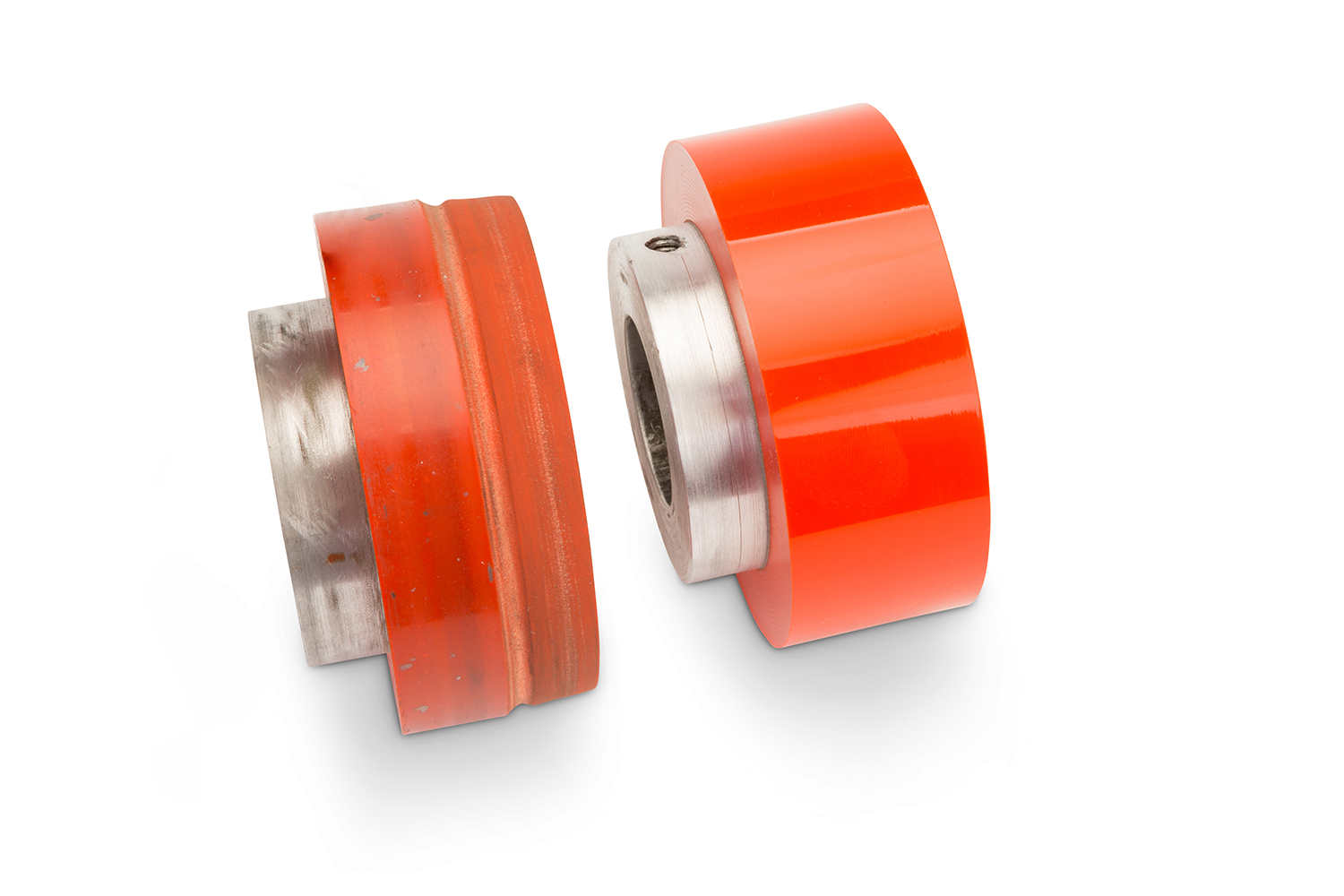

After nearly twenty years of replacing rubber rollers with expensive OEM rollers from overseas, the printing and converting company learned of the polyurethane molding and roller recovery services offered by Meridian Laboratory. Despite not having access to any drawings from the original equipment manufacturer, they simply sent worn out rollers to Meridian Laboratory for measurement of both size and durometer. The result in doing this was replacement rollers which reused their metal cores, but were now covered with Meridian Laboratory precision polyurethane ML6 material.

The precision polyurethane ML6 equipment rollers were not only considerably less expensive, but lasted longer and were delivered in a matter of days versus the weeks they waited in the past. They were also able to build a stock of replacement rollers from the surplus of metal cores they had accumulated. This made scheduling maintenance and downtime a predictable and profit lossless process. They were even able to realize higher print quality and less jams due to the superior finish and concentricity of Meridian Laboratory ML6 rollers.

Key Statistics

- Stripping and recoating worn rubber rollers with precision polyurethane ML6 reduced replacement costs and lead time

- Precision polyurethane ML6 equipment rollers were superior in surface finish and tolerances, resulting in print quality improvement and fewer jams

- Drastically improved maintenance scheduling and on-hand availability of parts