CASE STUDY

ROTOCON Rotary Electrical Connector Reduced Downtime and Improved Machine Output

Challenge

A worldwide designer and manufacturer of bottle filling and capping systems has relied on Meridian Laboratory’s multi-channel, Ethernet-equipped sealed slip rings for over 25+ years to provide maintenance-free, rotary electrical connections to all of their machines. After struggling for years with Ethernet communication packet loss and consistently having to maintain or replace brushes, they were able to eliminate all of these issues by switching to ROTOCON rotary electrical connectors.

For modern rotational bottle and filling stations to function quickly and efficiently, they rely on high speed Ethernet communication signals to transmit the variety of signals and inputs necessary to fill, cap, and package fluids within a container. Communication quality and transfer speeds are critical to avoid activating filling nozzles too early or too late, resulting in not filling bottles enough or overfilling. As an original equipment manufacturer, it is critical to its customers that their bottling and filling machines are both accurate and reliable – as any downtime translates directly into lost productivity and output. After struggling for years with maintaining and replacing conventional brushed slip rings placed deep within the center of the machine – the manufacturer knew they needed a slip ring that would provide them the reliable and high-speed Ethernet communication signal they required, with longer lasting and maintenance free results.

Solution

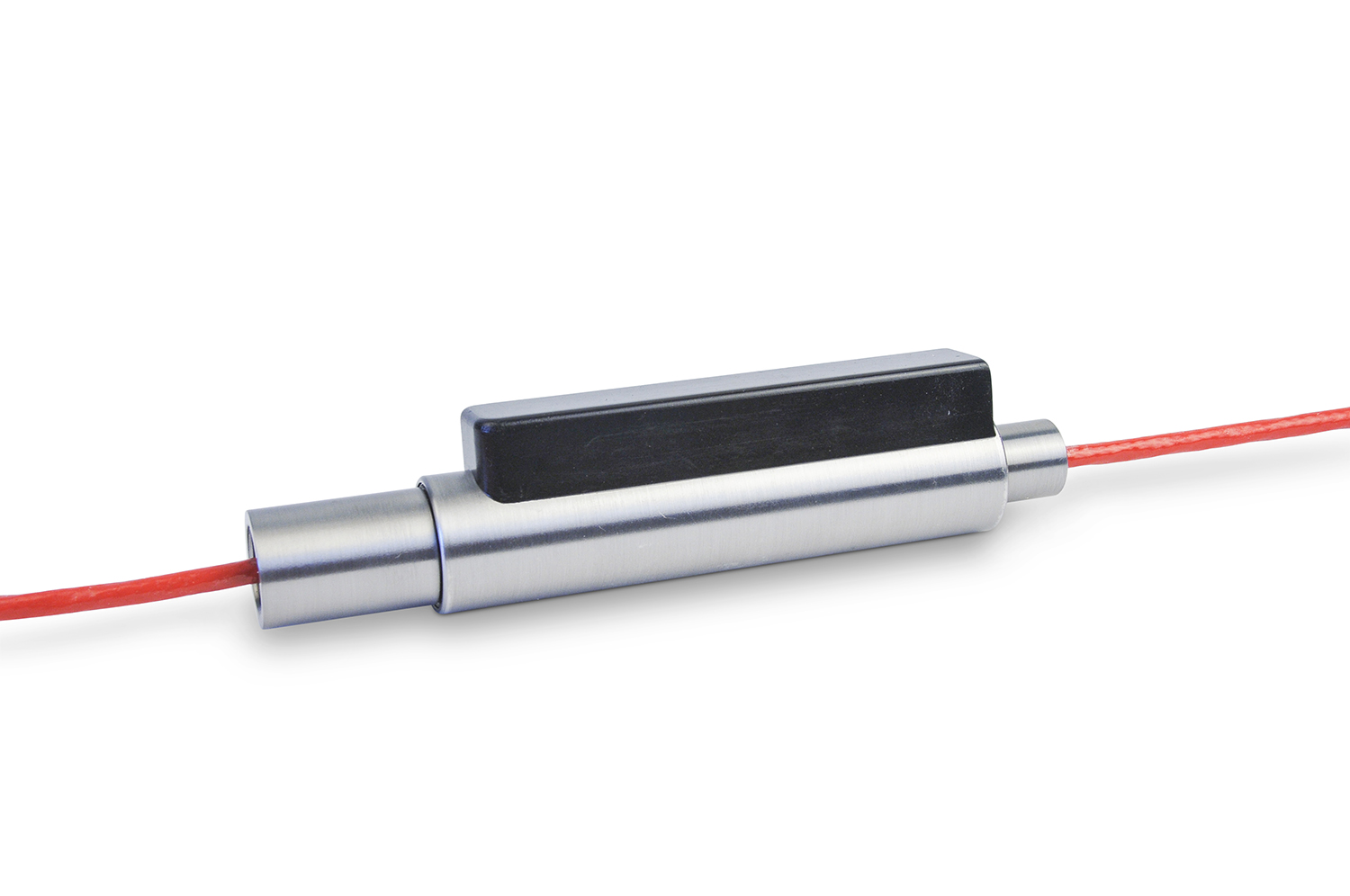

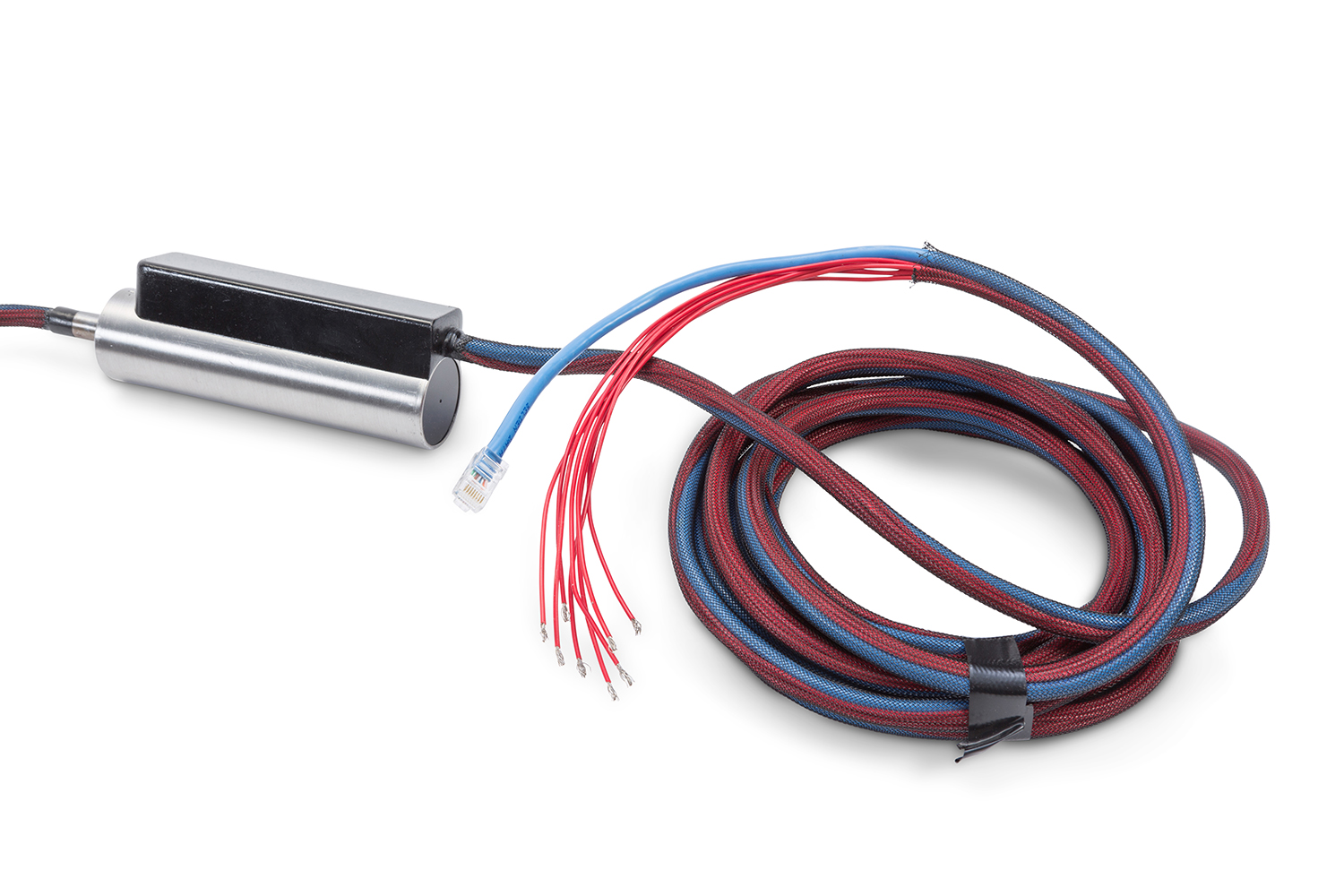

After discovering ROTOCON high performance sealed slip rings, the customer was able to work with Meridian Laboratory’s engineers to get four different sealed sip ring versions, ranging from eight to 15 channel slip rings to meet the requirements of their bottle and filling machines. ROTOCON rotary electrical connectors are capable of handling both PLC power/control along with Ethernet (and other) communication signals within the same assemblies. Prior to field usage, the customer let the new ROTOCON slip ring operate nine months without interruption in a test case, subjecting it to daily wash-down procedures. Using their prior conventional, brushed slip rings they would have had to perform field service operations three times during this period. Since converting to ROTOCON rotary electrical connectors, they have completely eliminated all problems faced with communication packet loss and signal quality. With the environmentally sealed design of all ROTOCON rotary electrical connectors, they were able to redesign the machine allowing for more efficient assembly and disassembly for internal teardown and maintenance of other parts of the machine.

Key Statistics

- ROTOCON’s Rotary Electrical Connector Eliminated all prior issues of Ethernet signal and communication packet loss

- Eliminated all maintenance previously related to conventional brushed slip rings

- Drastically reduced downtime and improved machine output