| RPM | Up to 15,000 RPM |

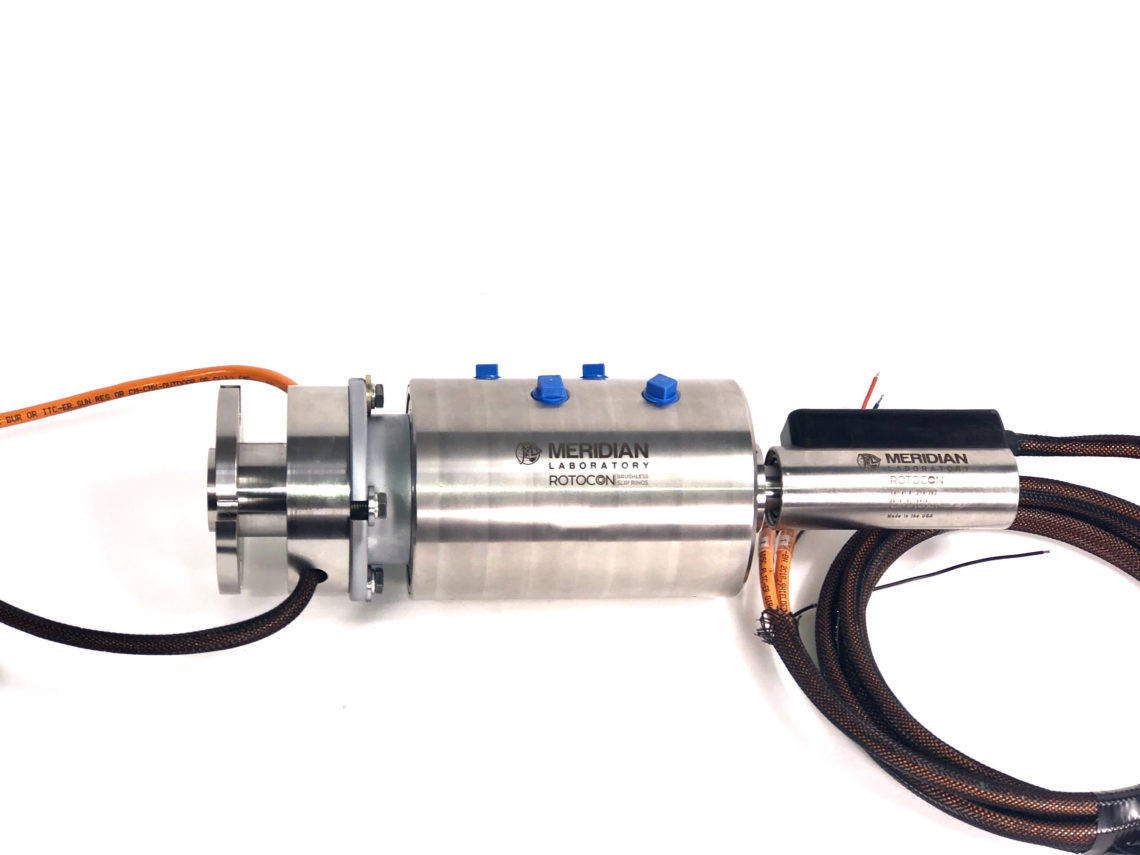

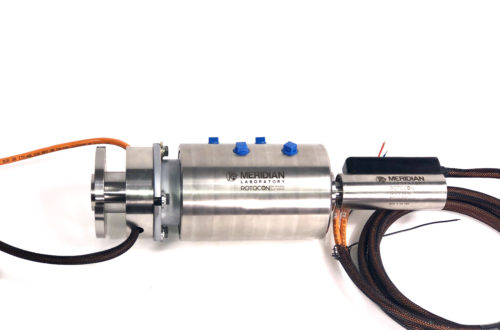

| MOUNTING | Through-hole, end of shaft, or flange mount available |

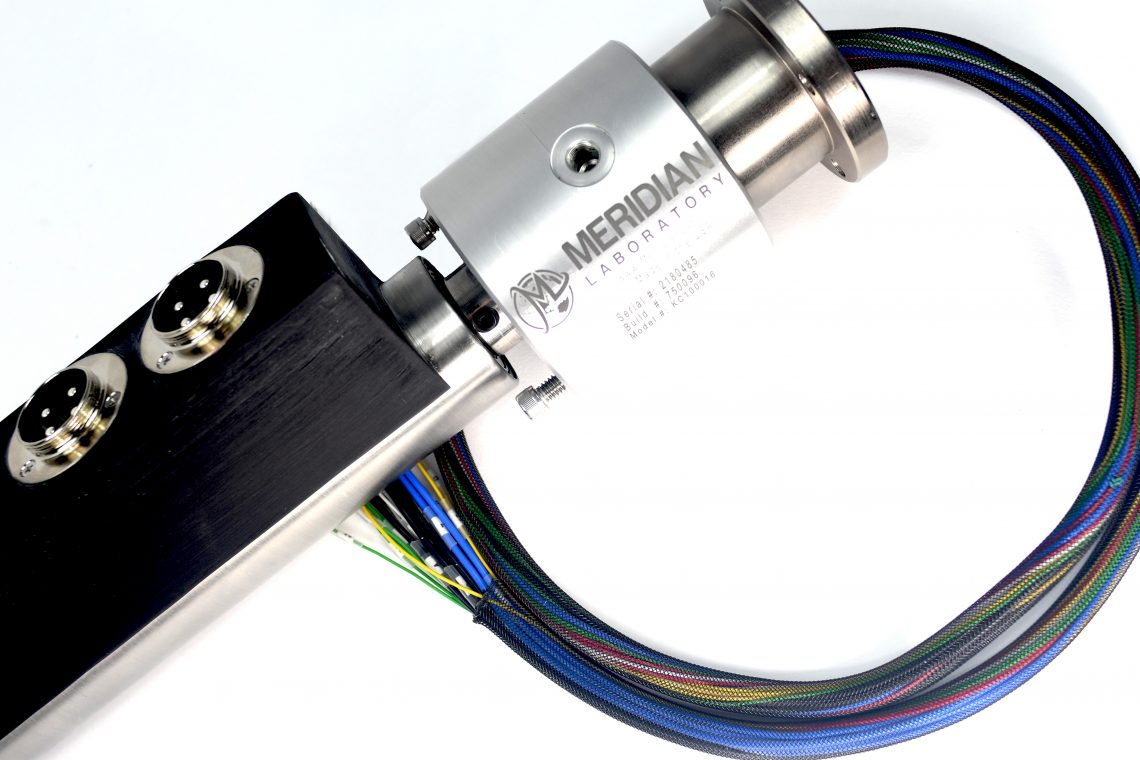

| HOUSING | 6061 Aluminum or 304 Stainless steel |

| PASSAGES | Up to 20 Passages |

| PRESSURE | Up to 23,000 PSI - speed and media dependent |

| TEMPERATURE | -321F to 900F, depending on options |

Nearly any of Meridian Laboratory’s ROTOCON Slip Rings can be combined with rotary unions