Blog / 2023.07.08

Just how bad is your rotary ground performing? A head-to-head comparison of rotating electrical grounds.

Rotary Ground Shootout : Sumner ST-107, Lenco Model C, Tweco RG-140 vs. Meridian Laboratory ROTOCON® ERG-400 Rotating Electrical Ground

Where and why are rotary grounds needed? Here’s where and how they work.

How does one electrically ground a rotating workpiece or application that utilizes high current, and why is it necessary? Where can one utilize a ROTOCON®, or any type of rotary ground, in a rotating application?

Numerous applications, including welding, plating, semiconductor manufacturing, and other typically high current processes will frequently complete their circuit from the positive and negative terminals through a ground clamp (more commonly referred to as the “ground”). Electrical current passes into a load, through it, and then exits via an equally rated wire or cable, returning back to the grounding point.

A common relatable example of this is the battery in your car, in which the positive side (terminal) energizes the starter (and other electronic parts of your vehicle), while the negative side of the battery is connected to the chassis (ground) of the vehicle. While a poor ground connection on a vehicle is different from a poor ground connection in an industrial or manufacturing setting, the effects are the same. With a poor ground connection, power is unable to efficiently transfer through the circuit or device due to an increase in electrical resistance, measured in ohms. In the case of the car battery, this will mean decreased power supplied to the starter, which in turn leaves you with a vehicle that will have difficulty starting because of insufficient current delivered to the starter.

Now, how does this apply to industrial settings and applications? If you work in an industrial, manufacturing, research or fabrication environment, chances are you work either directly or indirectly with a process that requires some type of rotating electrical ground; below are a few examples of where you might find a rotary electrical ground being used:

Welding

- Tank and Pipe Welding – Tanks, pipes and other welding applications require a rotary ground to transfer current while the tubes or material is rotated and welded to make stacked tubes and other welded end products.

- Car Frame Manufacturing – The average passenger vehicle frame consists of approximately 5,000 welds, oftentimes performed on a gimbal or turntable system with the weld head remaining stationary.

- Steel Structure Fabrication – Steel buildings, wind turbines and many other structural components require the ability to rotate work pieces while welding or between welds as the part is positioned.

- Automated and Semi-automated Welding Equipment – Welding tables, welding positioners and robotic welding all require the ability to transfer a consistent current while the work piece or welder are rotated or manipulated.

Plating and Electro Polishing

- As parts are inserted into an electroplating or polishing bath, they are oftentimes rotated to ensure even distribution across all surfaces of the parts being plated, resulting in a higher quality finish. Rotary grounds are necessary to provide a steady, consistent electrical current to the workpiece or fixturing as they rotate.

Microchip & Silicon Wafers

- Sputtering – Sputtering is the process by which a material is stripped of surface atoms by bombarding it with high energy plasma and gas. This process is commonly used in the production and processing of silicon wafers for microchip manufacturing.

- Sputtering Deposition – Sputtering deposition is the process by which a material is deposited onto a substrate through the removal of material through sputtering, then leaving that free material on the substrate.

- DC Sputtering Deposition – DC sputtering is a method of sputtering deposition that works best with conductive materials and metals, it is achieved by using a DC power supply as the source for the plasma.

- RF Sputtering Deposition – RF sputtering is a method of deposition that utilizes a high frequency (typically RF = radio frequency) electrical power signal to generate the plasma. This has the added benefit of being able to deposit on insulative targets because RF sputtering prevents charge accumulation on the insulative materials.

Rotating electrical grounds can be used in sputtering applications to provide a ground circuit to a rotating workpiece, ensuring an even application of deposited materials onto the substrate. Having a stable ground resistance allows the parameters to be more tightly controlled and monitored, providing a better end product.

To learn more about sputtering deposition and the processes involved, VAC COAT has a great blog detailing the processes and applications.

While the applications listed are some of the more common examples, there are countless others that require electrical current to be transferred from rotating to stationary or vice versa, which makes a quality slip ring or rotary ground essential for optimal performance in the system.

The Importance of Consistent Current Delivery in Rotary Grounds

Meridian Laboratory has engineered and manufactured the world’s foremost rotary grounding solutions since 1963. During this time, we have provided quality grounding solutions to both simple and complex applications worldwide, all with the same goal of providing consistent current delivery, without any type of maintenance or adjustment necessary.

This guide serves to show you multiple ways of grounding a rotating workpiece, and offers insight into the differences in quality and performance you can expect for your process. Like a vehicle or virtually any type of tool or product available on the market – there are multiple options to get the job done. For someone looking to improve the quality of their end product, reduce maintenance and downtime, and eliminate scrapped products due to non-conformance, this guide shows the performance benefits that only a ROTOCON® rotary ground from Meridian Laboratory can provide.

To begin, we will be demonstrating how each type of rotary ground works, along with the benefits and drawbacks associated with them.

Meridian Laboratory’s ROTOCON® ERG Rotary Ground

Here’s how it works:

Current is transferred through your cable, to the rotary ground, and into your workpiece. ROTOCON® ERG Rotary Grounds have multiple mounting options; they can be threaded directly onto or into a workpiece, flange mounted or mounted with a clamp.

Upfront Cost: Approximately $550.00

Meridian Laboratory ERG Rotary Ground Benefits & Drawbacks

The consistency of the current is unmatched. Meridian Laboratory ROTOCON® units are permanently sealed; the liquid metal contact is held under oil, with high performance seals and bearings. The 304 stainless steel housing permanently encases the contact, resulting in a durable product free from any ingress of contaminants which can compromise conductivity. Due to the seals utilized in the ERG design, the body temperature should not exceed 160°F. If your application is in a high temperature environment, something as simple as moving air over the body of the unit may be an adequate solution to reduce the temperature of the unit, Meridian Laboratory would be happy to discuss your application in further detail, please reach out with any project specifications or questions.

Benefits

- Current stability is unaffected by rotation or vibration

- Multiple mounting options

- Performs without grease, brushes, or metal on metal contact

- No maintenance required

- Robust industrial design provides reliable current and long lasting performance

- RoHS compliant versions available

- Rotationally tested to exceed 500 million revolutions

- Sealed and arc-free construction

- Easy to install

Drawbacks

- Not to be used in high-temperature environments exceeding 160°F

- Larger upfront initial investment

Braided Metal Strap & Clamp

Here’s how it works:

A conductive wire or strap is wrapped around a shaft and attached to a stationary ground clamp. As the workpiece rotates, the current is transferred from the workpiece, through the strap and exits via the ground clamp.

Upfront Cost: Approximately $65.00

Braided Metal Strap & Clamp Benefits & Drawbacks

This solution is likely the simplest way to ground a rotating device while providing current to it. It requires materials easily found in a hardware or automotive store. Although this method does provide an electrical ground, it will not provide consistent current delivery as the piece rotates. This apparatus will wear out quickly as the metal strap becomes worn from friction and arcing.

Benefits

- Low upfront investment

- Readily available

- Short term, simple solution

- Easy to use

Drawbacks

- Fluctuating current delivery

- Frequent maintenance required

- Constant adjustment or tightening required

- Not robust for industrial or continuous use applications

- Potential electrical arcs and sparks

Ball Bearings

Here’s how it works:

Current is transferred through the balls or rollers between the inner and outer races of the bearing. An additional component or carrier assembly is necessary then to attach an electrical cable lug to.

Ball Bearing Benefits & Drawbacks

While a bearing may provide a path for electricity to flow, passing current through a bearing can be inconsistent, and potentially destructive for the system. The materials in a bearing are typically steel. These materials are much more resistive than high conductivity metals such as copper. This high resistance (not including the effects on your power due to changing resistance) can be the cause of additional heat that can drive a bearing to failure. Although the components of a bearing are precision machined, the surfaces are not perfect and contain microscopic peaks and valleys. As the bearings rotate, the races and rollers of the bearings continually make-and-break contact. The current will flow through small micro-arcs between the balls and the race. These micro-arcs happen continually, slowly wearing away the contact surfaces of the bearing. These degraded surfaces compound the effects of the arcs, speeding up this process of degradation. Not only does this damage the functionality as a bearing, but also limits the ability to conduct electricity. While it may be trivial to replace a rotary ground that has worn out, it is much more difficult to repair a machine that has been damaged due to a failed bearing.

Benefits

- Readily available

- Relatively easy to manufacture

- Low upfront investment

Drawbacks

- Fluctuating current delivery

- Maintenance intensive

- Safety hazard due to arcing – while stationary or rotating

- Oftentimes costly and time intensive to replace

- Not robust for industrial or continuous use applications

- Reaches dangerously high temperatures while in use

Carbon Brush Block

Here’s how it works:

Current is transmitted through the carbon brush to the workpiece via surface contact. This is often referred to as a commutator block slip ring or brush block.

Carbon Brush Block Benefits & Drawbacks

The consistency of the current transferred between the carbon brush and the workpiece is largely dependent on the roughness of the carbon brush and the workpiece, as well as the cleanliness of each surface. Over time, the surfaces become pitted due to current arcing, dirty from the breakdown of the carbon and accumulation of dust, or rough and damaged from friction wear. Carbon brush grounds are the most popular method of conducting current in a rotating application due to their low cost, and common use in conventional slip rings.

Benefits

- Simplistic design

- Low upfront investment

Drawbacks

- Fluctuating current delivery under rotation

- Requires adjustment and replacement over time

- Potential safety hazard due to arcing and sparkings – while stationary or rotating

- Not robust for industrial or continuous use applications

- Maintenance intensive

- Needs consistent cleaning to ensure an electrical contact

Sumner ST-107 Rotary Ground

Here’s how it works:

Current flows from the clamp, through a pin to a bronze bushing via metal-on-metal contact, and exits through the ground cable attached to the swivel.

Upfront cost: Approximately $150.00

Sumner ST-107 Rotary Ground Benefits & Drawbacks

The consistency of the current being transferred is dependent on the metal-on-metal contact between the pin and bronze bushing. As the unit rotates, you will see frequent fluctuations in current as high as 10%. Over time, as the metal-on-metal contact begins to wear down, resistance will further increase, and eventually cause a failure or severe spikes in current from the friction generated on the wear surfaces.

Benefits

- Lower upfront investment

Drawbacks

- Fluctuating current delivery under rotation

- Requires adjustment and replacement over time

- Maintenance intensive

- Not robust for industrial or continuous use applications

Lenco Model C Rotary Ground

Here’s how it works:

Current flows into the copper shaft, which relies on a spring-loaded bolt to provide force to the metal-on-metal contact between the two brass surfaces, which rotate against each other during use.

Upfront Cost: Approximately $200.00

Lenco Model C Rotary Ground Benefits & Drawbacks

The consistency of the current transferred between the spring-loaded stud and the workpiece is largely dependent on the surface smoothness and cleanliness of each surface. Over time, the surfaces become pitted due to current arcing, dirty, and rough or damaged from metal-on-metal friction.

Benefits

- Low upfront investment

- Simplistic design

Drawbacks

- Fluctuating current delivery under rotation

- Requires adjustment and replacement over time

- Not robust for industrial or continuous use applications

- Reliant on spring loaded force to keep electrical contact

Tweco RG-140 Rotary Ground

Here’s how it works:

Current flows into the brass shaft, which spins in the center of a brass housing. This requires conductive grease between the two metal-on-metal contact surfaces during rotation. It also has an adjustment screw on the side to vary the amount of compression placed onto the shaft during rotation.

Upfront cost: Approximately $370.00 for the rotary ground, $622.00 with clamp.

Tweco RG-140 Rotary Ground Benefits & Drawbacks

The consistency of the current transferred between the clamp and the workpiece is largely dependent on the conductive grease. This style of rotary ground requires regular maintenance both from the periodic filling of conductive grease and adjustment of the tension bolt to keep the ground’s housing in contact with the rotating conductive shaft. Over time, the internal arcing between the housing and the conductive shaft will damage the Tweco rotary ground, further reducing its electrical conductivity and potentially seizing the unit, resulting in the need to buy a replacement.

Benefits

- Lower upfront investment

- Easy to install

Drawbacks

- Fluctuating current delivery under rotation

- Requires adjustment and replacement over time

- Maintenance intensive (greasing and adjustment)

- Not robust for industrial or continuous use applications

Summary of Rotary Ground Performance

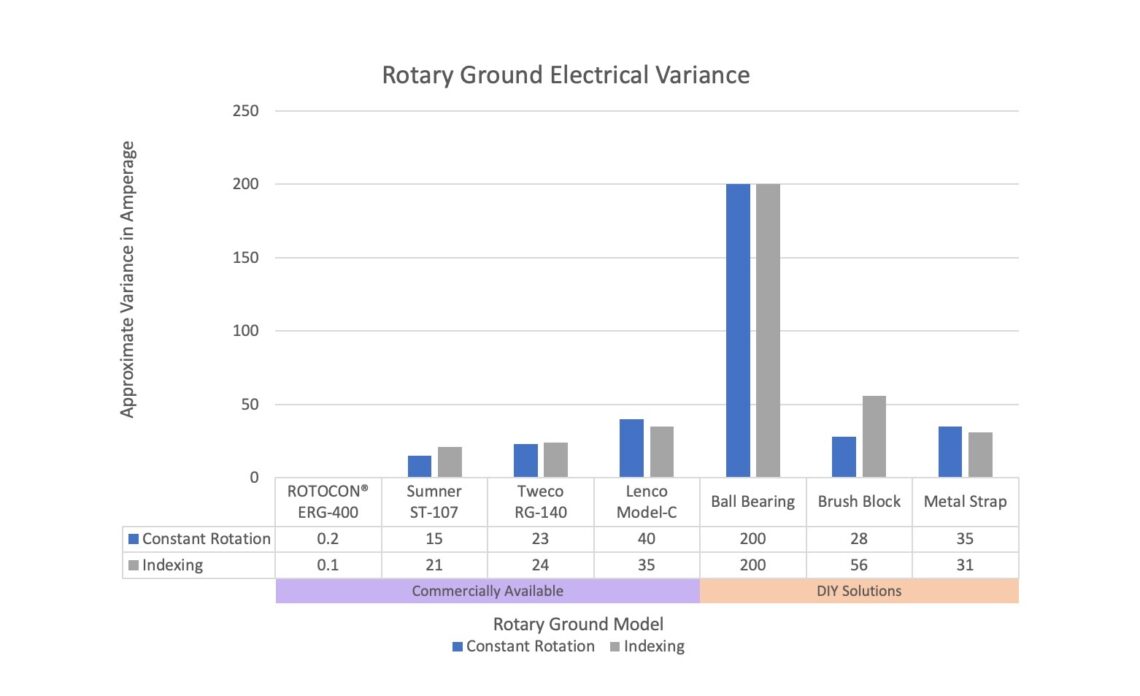

In the table below, you can see the variance in current between each of the 7 rotary grounds featured while under constant rotation and while indexing. Looking first at the “DIY” style of rotary grounds, we can see that the ball bearing performed the worst, with approximately 200 amps of variance under rotation, and the brush block performed the best with approximately 30 amps of variance. It is important to keep in mind their performance will not be consistent and gradually worsen over time. They also require frequent maintenance, adjustment, and eventual replacement.

Of the metal-on-metal style rotary grounds, the Sumner ST-107 performed the best with approximately 15 amps of variance under rotation, while the Lenco Model-C performed the worst with approximately 40 amps of variance.

Comparing these to the ROTOCON ERG-400, even the best metal-on-metal contact rotary ground showed nearly 200X the amount of current fluctuation compared to the ROTOCON ERG-400 – which fluctuated by only 0.1 amps.

There are many commercially available rotary grounds which all follow the same basic principles of metal-on-metal contact, wearing against each other to conduct current. Commercially available models include: Powerweld Ecr600L, Nies SH-440, Javelin RG400, Atarstore 600, Sumner ST-107, Tweco RG140 and Lenco Model C.

There are numerous ways to ground a rotating workpiece for high current applications. The market for rotary grounds is saturated with metal-on-metal contact solutions which deliver varying degrees of quality and electrical resistance. It is important to factor the longevity, performance, and consistency of your rotary ground along with the frequency and costs of properly maintaining and replacing them. While some solutions can be inexpensive upfront, all metal-on-metal contact rotary grounds require routine maintenance, adjustment, and replacement resulting in lost productivity, increased labor costs, and increased replacement parts expenses.

If you are looking for a long-term, maintenance-free rotary ground that delivers dependable and consistent electrical current every time, then the ROTOCON® ERG Rotary Grounds is the right fit for you. Please feel free to contact Meridian Laboratory with any questions or upcoming projects, we look forward to working with you.

Customers who rely on ROTOCON® rotary grounds!