Blog / 2017.09.27

ML6 and the Language Master, the History of High-Precision Polyurethane

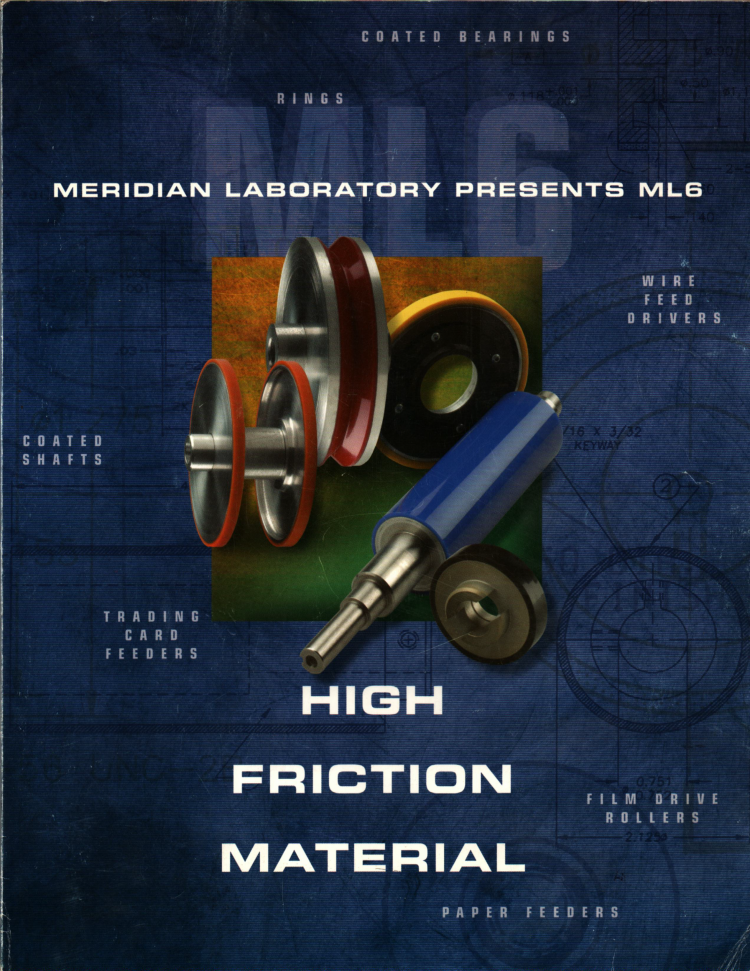

Innovation has become a business buzzword -everywhere you look some company is claiming they are the innovative, creative, thought leaders in their space. The only way to tell who the real innovators are is by seeing who was there first. To illustrate why Meridian Laboratory is a true innovator, read on about the history of the ML6 high-performance polyurethane line, its successes, product evolution, and most importantly, a proven record of innovation that shows how Meridian Laboratory has thrived for more than 50 years.

The 1960’s and the Language Master

It was in the early 1960’s that ML6 Polyurethane coatings were first developed. In a bit of good fortune, Meridian Laboratory was asked by a potential client to solve an issue with the Language Master, which allowed speech therapists to work with patients by recording the proper pronunciation of problem words on a magnetic strip card, to be played back later for practice. The cards were fed through the machine by rubberized rollers, which after a few years would break down, causing miss-feeds that would damage the cards and ruin the machine. While Meridian Laboratory had never worked on a problem of this type, their expertise and creativity were well known.

Seeing the problem as a worthy challenge, the Meridian Laboratory engineering team researched potential alternatives and improvements. After researching possible compounds that could be of use, the team contacted a company in Illinois that had been working with Polyurethane in larger-sized applications, such as creating piping, seals, large rubber containers, and alternative car tires. The first attempt to use this material for coating on small rollers was a failure. The material was very durable and had good wear characteristics, but was not precise enough for such a delicate application.

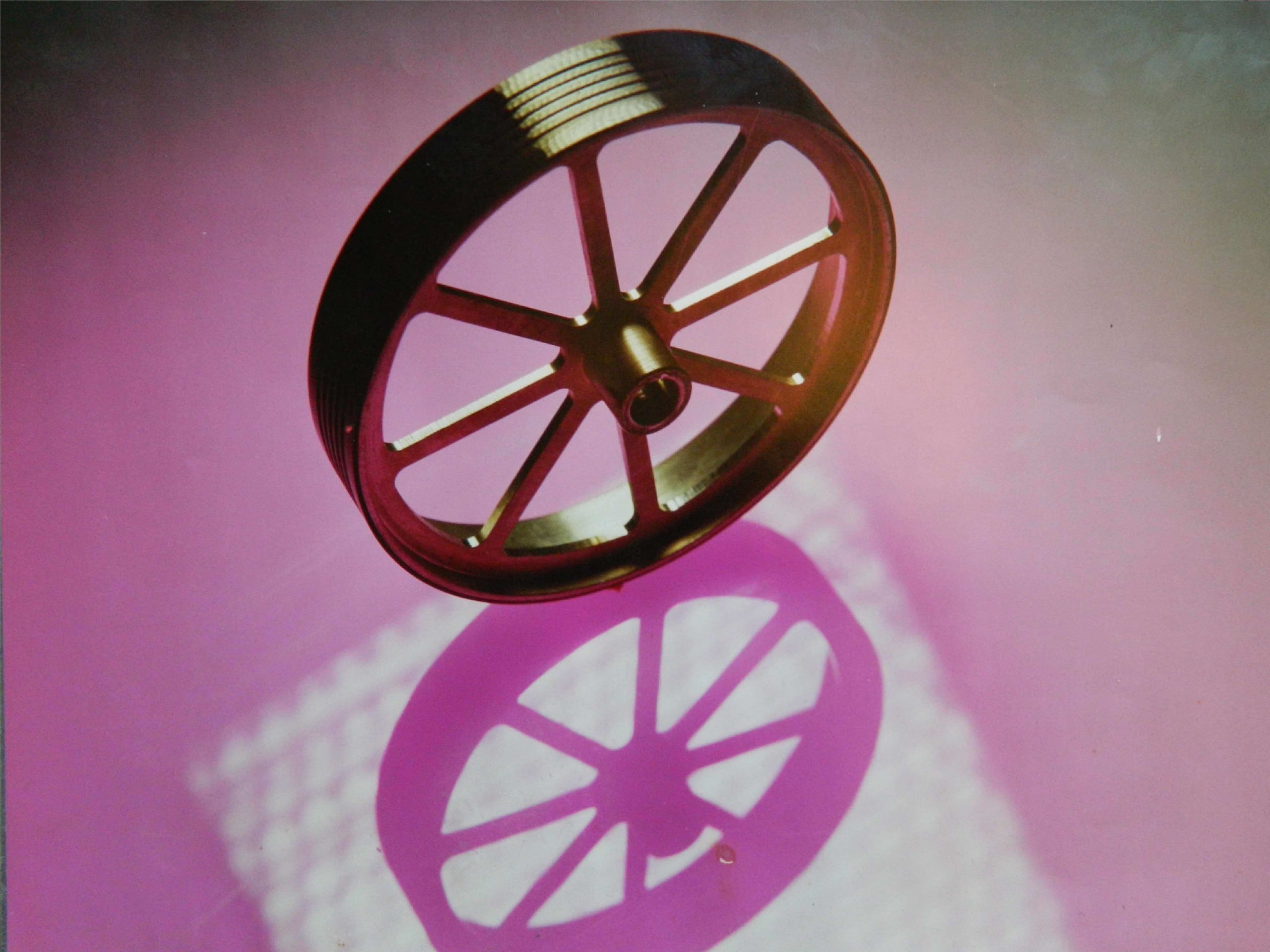

The Meridian Laboratory team decided to create an original formula to fit the needs of this new application. This altered Polyurethane compound became the base formula for what is now ML6, and allowed Meridian to control the dimensions of the Polyurethane down to 0.001″ accuracy. ML6 now had everything the Language Master needed to move the card precisely and significantly increase the longevity of the machine. The positive reaction to the new material from the Language Master team was so strong that Meridian Laboratory started to market ML6 High Performance Polyurethane at tradeshows, and began selling drive rollers coated in ML6 in addition to the ROTOCON line.

The 1970’s, Dawn of the Computer Age

In the 1970’s, as computers became an area of increasing interest to universities and research laboratories around the country, Meridian Laboratory was there to solve a familiar problem. Computers were originally fed data through punch cards, much in the same way that the Language Master was fed its recordings. These punch cards were most commonly made from paper and contained bits of code on them, which were logged on the computer in the exact order they were fed through by the rollers. Similarly to the Language Master, these rollers would wear out, become unreliable, and ruin the order of the line of code, requiring the technicians to start all over from the very first card.

The ML6 formula had the same advantages in durability and efficiency to computer rubber rollers as it did to the Language Master’s rollers, and Meridian Laboratory quickly became one of the go-to sources of polyurethane rollers for high-level research institutions around the country.

ML6 and Magnetic Tape in the 1980’s

As punch cards gave way to magnetic tape for storage of data, ML6 began to adapt to the difference in roller coating needs. Magnetic tape was the preferred method of data storage and transfer for many popular products such as 35MM cameras and VHS tapes. It was also far more delicate and precise than paper punch cards and required a level of roller coating uniformity that other products couldn’t match. ML6’s reliable quality allowed tape to be fed at a faster rate than with rubber rollers, because there was no need to worry about blemishes on the coating that might damage the fragile tape as it sped through.

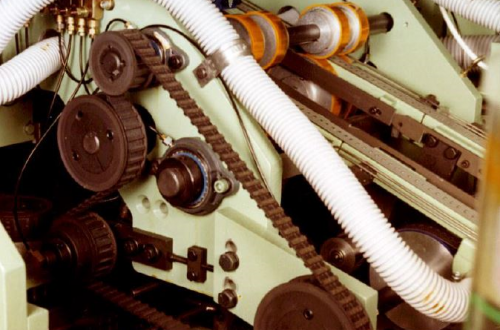

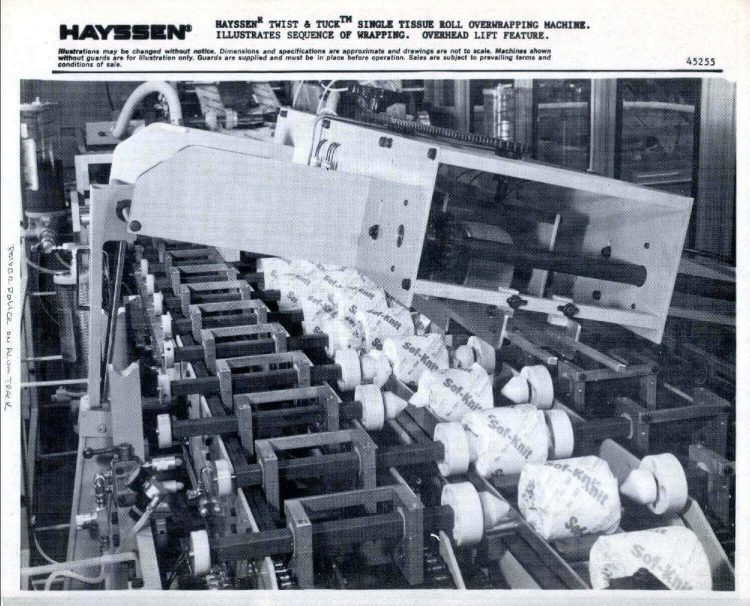

As computers grew faster, smaller, and more common, industrial manufacturers began to use them to run the machines in their factories, allowing assembly lines to speed up and stop less. Under these conditions, rubber rollers simply could not hold up. One company, Hayssen Manufacturing, used ML6 to increase their assembly line rollers from 50rpm to 500rpm, greatly increasing output, productivity, and decreasing the costs of standby time due to maintenance. As the computer powered industrial world started to sprint faster and faster, ML6 grew to cater to these markets.

The 1990’s and Rapid Line Expansion

In the 1990’s technology growth in the manufacturing industry began to decline and the Meridian Laboratory team began to look for new ways to apply their ML6 formula. The first step was to broaden and standardize the product lines and offerings, to avoid limiting the ML6 material to industrial uses. With a little customization of the formula and ordering processes, ML6 could now be commissioned for use in everything from 6000 roller manufacturing machines, to a small order for custom skateboard wheels. As potential applications expanded, the volume of ML6 product manufactured increased significantly, but the quality of the product never faltered.

2000-2010, The Era of Diversification

Following in the footsteps of the 1990’s, the early 2000’s was a period of great diversification of applications and uses for the ML6 Polyurethane material. The Meridian Laboratory engineers showcased their creativity in the design of materials to solve obscure and unique problems, including coating sockets for airplane manufacturing to prevent damage to paint, or creating custom tips for the fingers of a bomb-defusing robot.

The Future of ML6 Polyurethane

Meridian Laboratory’s recipe for success has remained the same and it has never stopped seeking new horizons for its product line, the range of new applications for Polyurethane ML6 grows every year.

Do you have a perfect application for ML6 High Precision Polyurethane? Contact Meridian Laboratory today!