A manufacturer of custom polyurethane solutions – precision, high quality, fast lead times

Custom Cast & Molded Polyurethane Parts

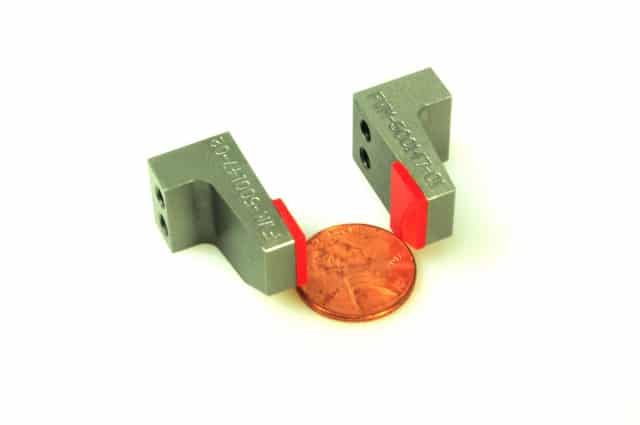

CUSTOM MOLDED POLYURETHANE PRODUCTS

Since 1963, Meridian Laboratory has been a leader in delivering precision polyurethane drive rollers, idler rollers, encoder wheels, coated cam followers, covered bearings, flat sheet, and other molded polyurethane products. Meridian Laboratory has an extensive collection of standard parts in a wide range of shapes and sizes. Despite this, what sets Meridian Laboratory apart from conventional custom molded polyurethane manufacturers is our ability to deliver quick, precise, yet cost effective prototype and low volume molded polyurethane solutions.

With the unique manufacturing technique used to produce ML6 molded polyurethane parts, Meridian Laboratory has the ability to scale output with time as need and quantity grows. This allows Meridian Laboratory to adequately support projects from single prototypes to high-volume production, in an efficient and cost effective way – supporting our customers throughout the entire process with high-quality, molded polyurethane parts.

Meridian Laboratory has the ability to deliver low and high volume molded polyurethane parts including:

- Urethane Covered Drive Rollers and Wheels

- Urethane Idler Rollers and Wheels

- Coated Cam Followers / Track Rollers

- Coated Ball Bearings

- Coated Yoke Rollers

- No-Crush Wheels

- Urethane Coated Shafts

- Urethane Covered Grippers

- Polyurethane Tubing and Sheets

- Encoder Wheels

- Custom Molded Polyurethane

MERIDIAN LABORATORY’S CUSTOM MOLDED POLYURETHANE PROCESS

Meridian Laboratory has made the process of developing custom cast and custom molded polyurethane components, easy and efficient.

- Contact Meridian Laboratory with specifications, drawings, or the part you wish to have made.

- In the event Meridian Laboratory does not have pre-existing tooling which fit your needs, a recommendation will be provided on pre-existing tooling and sizing.

- If you require specialized tooling, a one-time setup charge (generally between $300-$1,000) and is good for the lifetime of the parts’ dimensions.

- Specify if you would like to send parts to Meridian Laboratory, or have us deliver the part complete to print.

- Typically, in 12-15 business days you will receive your first parts for testing and evaluation.

- As demand and quantities scale, so can Meridian Laboratory’s output and production capabilities to meet your needs.

- After the parts are delivered, you can expect periodic check-ins from us – it is our priority to make sure they not only exceed your expectations, but deliver the industry leading performance and longevity for which we are known for!