Reduce Downtime and Replacement of Parts for drive wheels, idler rollers, cam followers, custom parts and solutions

ML6 Precision Polyurethane for Factory Automation

ML6 PRECISION POLYURETHANE PRODUCTS REDUCE DOWNTIME AND REPLACEMENT OF PARTS

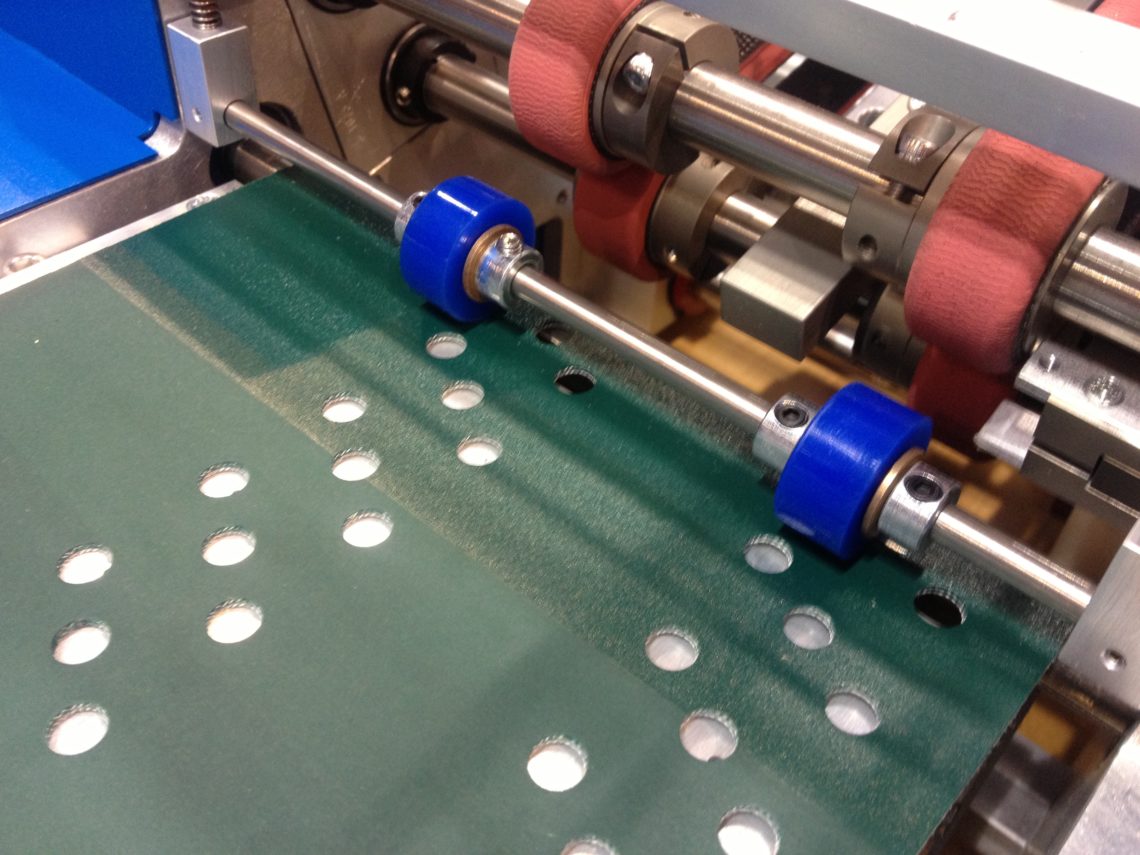

Meridian Laboratory’s ML6 precision polyurethane products supercharge drives, brakes and idlers for manufacturing and factory automation. The ML6 process has been specifically engineered for industrial applications over 55 years of working with the world’s top manufacturers and brands.

- Specific applications: Sheet glass production, window manufacturing & assembly, steel production, stainless steel appliance assembly, glass tube production, wire and cable manufacturing, robotic assembly, aerospace assembly.

- Client testimony: “By utilizing Meridian Laboratory’s ML6 polyurethane products we were able to reduce the rate which we replaced our rollers by over half, with the precision and quality being even higher than our old provider.”

- Nearly half of all manila envelopes produced in North America come in contact with ML6 precision drive rollers!

If you design, manufacture, or service factory automation equipment and machines, you should be aware of the benefits which Meridian Laboratory is able to provide to your machine or equipment. Whether your fully or semi-automated application requires a process which drives, idles, indexes, or converts you can rely on Meridian Laboratory’s ML6 precision polyurethane products to reduce downtime, reduce the number of rejected parts, maximize productivity and output.

THE IMPORTANCE OF PRECISION ROLLERS FOR FACTORY AUTOMATION

While it’s easy to think “it’s just a roller”, it’s even easier to lose sight of how much you ask of your rollers and wheels, day in and day out. Keeping your operations running with a minimum of downtime for machine repairs, feed jams, or other time wasters (and money costers) means upgrading to superior components for your application. If you expect, and demand that your equipment do more, ML6 offers a proven upgrade you’ll notice immediately.

Take a look at the short video below to see one (of many) very simple reasons a more durable, precision roller can have a huge impact on your manufacturing environment.

REDUCE DOWNTIME AND REPLACEMENT OF PARTS FOR DRIVE WHEELS, IDLER ROLLERS, CAM FOLLOWERS, AND CUSTOM SOLUTIONS

- All tolerances guaranteed within 0.001” or better

- Meridian Laboratory works directly with raw ingredient manufacturers to deliver a finished product, specifically tailored for manufacturing and industrial processes and applications

- Longer lasting over conventional ground urethane compounds and manufacturing techniques

- Non-marking surface great for converting and material handling and assembly applications

Use the links below to browse a selection of ML6 Precision Polyurethane coated wheels, rollers, bearings, bushings, and other components designed for factory automation, or use the button below to submit an RFQ with your blueprint or specifications.

Contact Us

Phone: 608-836-7571

Toll-Free: 800-837-6010

Fax: 608-831-0300

Email: info@meridianlab.com

Meridian Laboratory

Meridian Laboratory

2415 Pleasant View Road, Middleton

5.0 47 reviews

-

PJ Degnan ★★★★★ a week ago

Excellent service! We faced Meridian with a difficult part to make and asked for perfection. They took the challenge on and through repeated effort and determination, Vance and the team were able to get us the "perfect" product … More we needed. Although this was undoubtedly a frustrating project for all involved, they saw it through and proved Meridian Laboratory to be exactly the company we needed and want to work with in the future. Great work! -

Griffin Speicher ★★★★★ a month ago

Adam and the crew at Meridian Laboratory were a pleasure to work with! Adam was extremely helpful, knowledgeable, and responsive. A slipring was purchased through Adam for the use of a university engineering capstone project, he was eager … More to help and very nice throughout the entire process to ensure our needs were satisfied. The slipring shipped and delivered in a timely manner and once the unit was received, all expectations were exceeded. The fit and finish of the slipring was great, and it performed exactly as expected. I highly recommend Meridian Laboratory if you require the use of a slipring, as I cannot say enough good things about the team over there and their American made products -

Adam Sandahl ★★★★★ 2 months ago

We contacted Adam Ellingson of Meridian Laboratory about acquiring a high-speed 3 channel ROTOCON slip-ring for our university capstone project. Mr. Ellingson was gracious enough to provide our team with a 6 channel slip-ring that performed … More excellent out of the box. The slip-ring assembly feels precisely machined and spins true with little mechanical resistance. It was the perfect product for testing our axial flux generator design and the extra channels came in handy. We appreciate the ease of mounting and excellent support from Mr. Ellingson. -

Aditya Gupta ★★★★★ 7 months ago

Amazing place to work as a engineering student to practically apply my learnings. The team is respectful and supportive to me. I never lack things to do while I am working. The flexibility I have is amazing which helps with conflicts in … More my schedule. My boss pushes me to grow while still being respectful to not overwork me or waste my time. Overall, working here is super valuable to growing my skills as an engineering student. -

Cory Barthel ★★★★★ 10 months ago

Meridian Laboratory consistently delivers quality products and services. Their slip rings and other rotary parts are among the best in the world. Additionally, they provide excellent customer support.