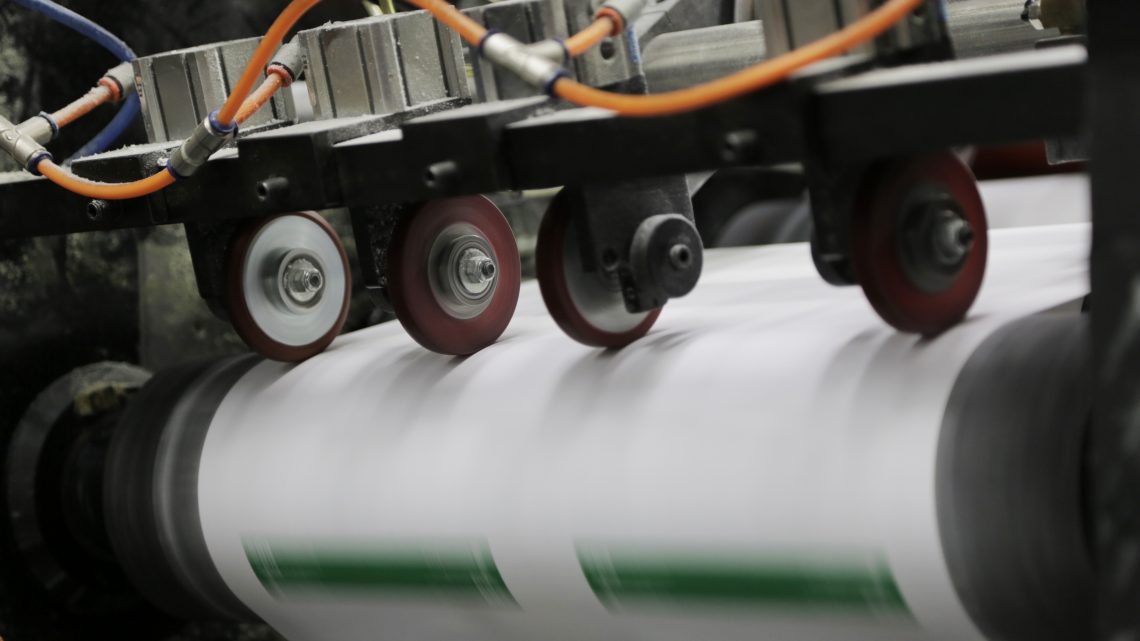

ML6 Polyurethane Matte Finish Rollers Drive Thin Rolls of Plastic Films

Challenge Polyurethane rollers were being used in the packaging industry to drive…

POLYURETHANE FEED ROLLERS ENGINEERED FOR PERFORMANCE AND PRECISION

Challenge Polyurethane rollers were being used in the packaging industry to drive…

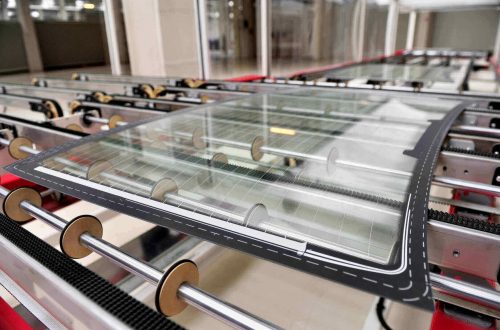

The Problem In the manufacture of glass, consistent quality is everything. Any…

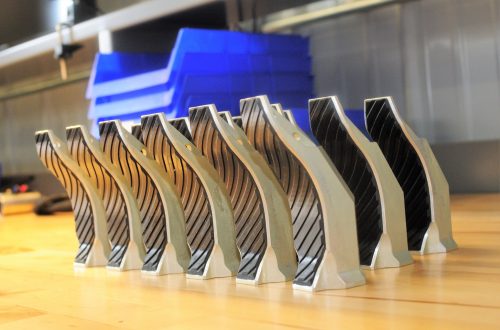

Challenge The world’s largest manufacturer of manila envelopes and folders, contacted Meridian…

Meridian Laboratory was able to greatly diversify its product application and polyurethane…