ROTOCON Ground Clamps Provide Quick ROI for Rotary Tank Welding Applications

With over 100 years of experience in pioneering the compressor, air conditioning,…

Meridian Laboratory has over 55 years of experience in designing and manufacturing standard and custom rotary electrical connectors for a variety of industries and applications. By taking the time to understand your project objectives, Meridian Laboratory can ensure a quality, long-lasting, and high-performance solution is delivered.

Understanding the voltages within an application is important in order to ensure a properly specified rotary electrical connector is provided, and failures such as shorts and crosstalk, do not occur. Almost all of Meridian Laboratory’s slip rings are rated to a minimum of 600V and extend in capability from there. Meridian Laboratory can support up to 5,000V in multi-channel configurations and a limitless AC/DC voltage for its single contact, MC-Series rotating grounds. Having a good understanding of the voltage requirements also allows us to select the most cost-effective and optimal ROTOCON rotary electrical connector for your needs.

The required amperage of an application is one of the most important pieces of information to know in specifying a slip ring connector. Meridian Laboratory has over 5,000 standardized ROTOCON rotary electrical connectors to meet your needs with a wide array of current carrying designs and capabilities. By knowing the maximum and average current draw for each portion of the application, Meridian Laboratory can specify a rotary electrical connector that meets your exact needs and is not overbuilt. It should be noted that all of Meridian Laboratory’s slip rings are rated to 100% duty cycle in terms of current draw with a considerable safety margin built into the design to account for surges in current that could occur during startup or normal use.

The duty cycle related to current draw typically comes into factor only when you are attempting to use a lower rated slip ring, given a relatively low duty cycle. Meridian Laboratory ROTOCON slip rings do not in any way become permanently damaged or susceptible to failure in over-current situations (even under 100% overload) – however, continuous use at an elevated amperage that is too high for the wires of the ROTOCON slip ring or rotary welding ground, will lead to elevated temperatures and increase the risk of premature failure.

The RPM is important to know in order to specify the correct slip ring for your application, or provide additional provisions to allow for high speed usage. Due to its unique design, nearly all ROTOCON rotary electrical connectors can be rotated at a speed which exceeds conventional brushed slip ring contacts. However, in high speed applications that exceed the nominal RPM rating of a ROTOCON, Meridian Laboratory can add air cooling or liquid cooling methods to keep the ROTOCON cool due to heat generated from rotation.

The electrical frequency or type of signal being transmitted through the rotating electrical connector is important information to properly specify the correct ROTOCON model for an application. All ROTOCON rotary electrical connectors can support low level signals, provided the correct cable type is specified. ROTOCONs can support all types of communication protocols including Ethernet (10/100/1000Mbps), Etherlink, LAPPNet, Profinet, Profibus, ControlNet, DeviceNet, CAN-Bus, RS485, RS422, USB (1.0/2.0), Modbus, EtherCAT, CC-Link, coaxial and many other types, provided the proper wiring and number of channels is accounted for. Meridian Laboratory ROTOCONs can also handle other low level signal types such as thermocouples (all types) and resistive temperature detection (RTD) without misreading or skewed results, due to the unique design of ROTOCON rotary electrical connectors.

In high frequency applications (generally greater than 250 MHz) it is important to communicate with Meridian Laboratory the details of the application due to electrical skin effect having effects on the rotary electrical connector. In these cases, Meridian Laboratory has specialized designs and features which can still accommodate these high frequency signals being used for an application.

Meridian Laboratory offers single contact rotary grounds all the way up to 100+ multi-channel units in a variety of sizes and options. For this reason, the number of contacts or channels an application requires is generally one of the earliest, and most important questions to answer to specify the proper product series of ROTOCON rotary electrical connectors.

Currently, Meridian Laboratory does not offer a type of pancake style slip ring – therefore as the number of channels increases, the axial length of the ROTOCON will grow. If space is a concern, Meridian Laboratory can sometimes enclose an end-of-shaft (M-Series) rotary electrical connector within its through-hole (MXT-Series) to save on axial length.

With any type of slip ring, a single track or channel is needed for each wire or cable that is used in the application. Therefore understanding the number of channels or signals being used is critical to properly select a ROTOCON rotary electrical connector.

Understanding your space requirement for rotary electrical connectors is important, as Meridian Laboratory has the ability to meet your critical space envelope. We do this by reducing or combining the channel count of an assembly, or concealing one ROTOCON rotary electrical connector within the through-hole of another ROTOCON rotary electrical connector.

Meridian Laboratory has a variety of configurations and options to best meet an application’s mounting needs. Most commonly Meridian Laboratory offers end-of-shaft (M-Series) rotary connectors, with a variety of options such as standard and custom shaft mount flanges, as well as body mounting flanges.

For projects which require mounting over a shaft or media such as air, water, or hydraulics to be sent through the center, Meridian Laboratory also offers its through-hole ROTOCON MXT Series with diameters up to 4.00”. This can be combined with rotary unions up to 20 passages for a combination swivel consisting of electrical slip ring and fluid/pneumatic.

Meridian Laboratory ROTOCON slip rings are typically rated to operate in environments up to 160°F, however there are provisions to allow for operation in warmer environments as well. For these types of applications, Meridian Laboratory can integrate liquid cooling jackets and mechanisms to ensure the rotary electrical connector does not overheat. Doing this ensures maximum longevity and performance during the operation of your ROTOCON slip ring.

Meridian Laboratory has the flexibility to design and manufacture single piece rotary electrical connectors and increase the volume of production to runs of hundreds per month. By understanding your current and potential future needs, Meridian Laboratory can best be prepared to meet your requirements in a timely and cost effective manner.

Meridian Laboratory has single channel rotary ground clamps rated up to 10,000A and multi-channel connectors up to 100 channels total, offered in a variety of standard configurations. Often, electrical configurations and application needs change over time, and customers wish to add more data and signal sensors, or more motors, heaters, or other high current devices. By adding these channels upfront, you can preemptively account for any future needs without having to configure and order a new ROTOCON rotary electrical connector. Although it is rare, in the event of a single channel no longer functioning properly, having spare channels allows you to move the malfunctioning channel to an unused one and temporarily continue operation status quo.

Meridian Laboratory offers standard and custom ROTOCON slip rings designed for a variety of industries, primarily centered around industrial, production, research, and heavy-use applications. Meridian Laboratory has developed a variety of options which can assist in rugged and harsh environmental installations. Understanding whether or not the rotary electrical connector will come in contact with liquids or other mediums helps us add things such as potted connectors, flying leads with terminations to junction boxes, and other sealing methods that help maximize the longevity and performance of the ROTOCON slip ring.

Meridian Laboratory has over 55 years of experience in designing and manufacturing standard and custom rotary electrical connectors for a variety of industries and applications. By taking the time to understand your project objectives, Meridian Laboratory can ensure a quality, long-lasting, and high-performance solution is delivered. If you are already using a traditional brushed slip ring assembly, providing information such as type, brand, or model numbers will help Meridian Laboratory cross-reference product specifications. By understanding what issues you are having with your current slip ring, and what objectives or the goals of your project are, Meridian Laboratory can also select or design and build the best solution to meet your needs. Whether the objective is to eliminate maintenance, improve signal quality, or simply select a high-performance rotary electrical connector, Meridian Laboratory has helped thousands of customers succeed in achieving their goals by understanding those goals from the start.

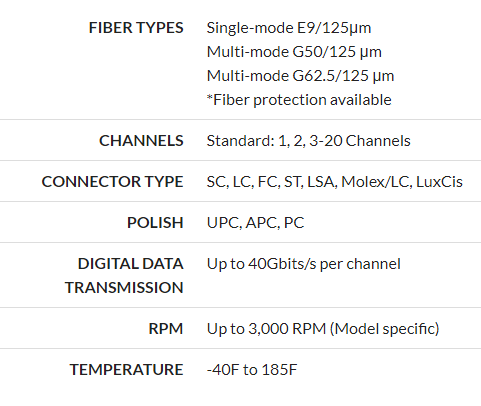

While Meridian Laboratory’s core business is in designing power and signal ROTOCON rotary electrical connectors, Meridian Laboratory can also integrate fiber optic rotary joints (FORJ) for added features and functionality. A full list of its capabilities include:

In applications which require both electrical power or signal and gas or fluid mediums to rotate freely, Meridian Laboratory offers rotary unions as well in a variety of passage counts and models. A full list of capabilities of our RU-Series offerings can be found here.

Meridian Laboratory also offers full integration with a variety of standard and custom encoder solutions in order to measure shaft position and rotation, such as in indexing turntables and rotary fillers or cappers.

Meridian Laboratory’s wide range of electrical and mechanical solutions continuously helps manufacturers, engineers, and machine builders solve complex problems, decrease down-time and increase productivity. Contact Meridian Laboratory today to learn how its standard and customized solutions can help improve your process, machine, or application.

With over 100 years of experience in pioneering the compressor, air conditioning,…

A thriving, local business with a 50-year history in commercial printing and…

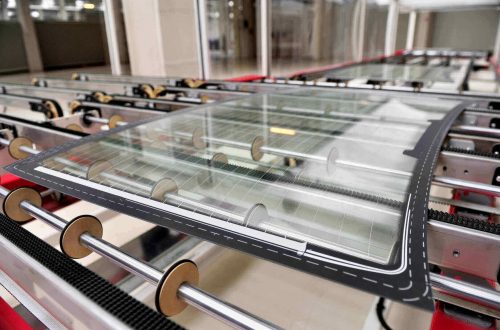

The Problem In the manufacture of glass, consistent quality is everything. Any…

Challenge An American based manufacturer of helicopter blades approached Meridian Laboratory with…