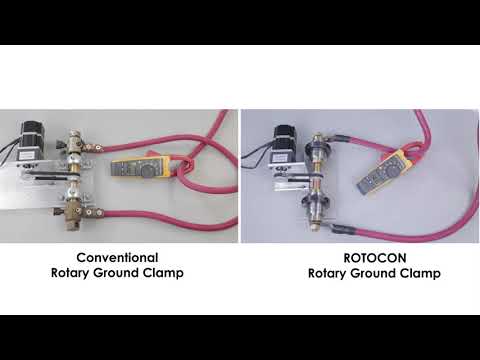

Tired of poor rotary ground consistency? Consistently having to grease and maintain a metal-on-metal rotary ground? Is fluctuating resistance causing variable consistency in your process, leading to scrapped product? If you are experiencing any of these problems associated with traditional rotary grounds, a ROTOCON rotary ground is the solution.

Video: ROTOCON ERG – Electrical Rotary Ground Contact Resistance Demonstration

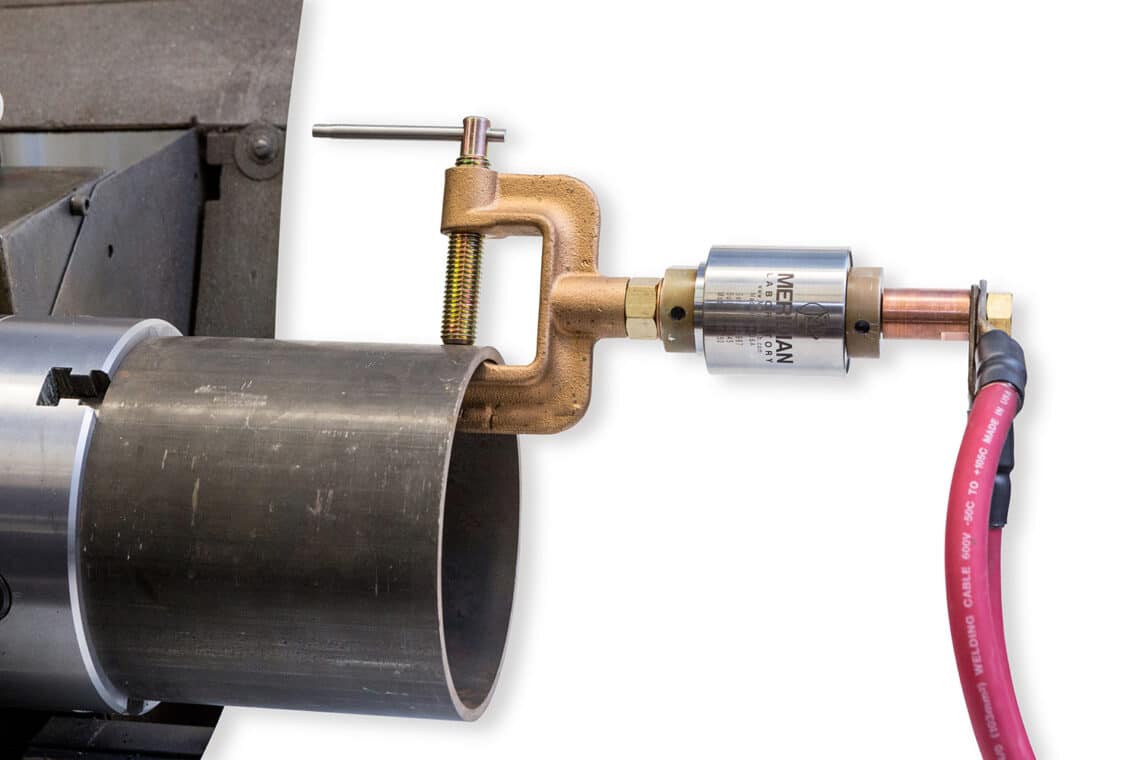

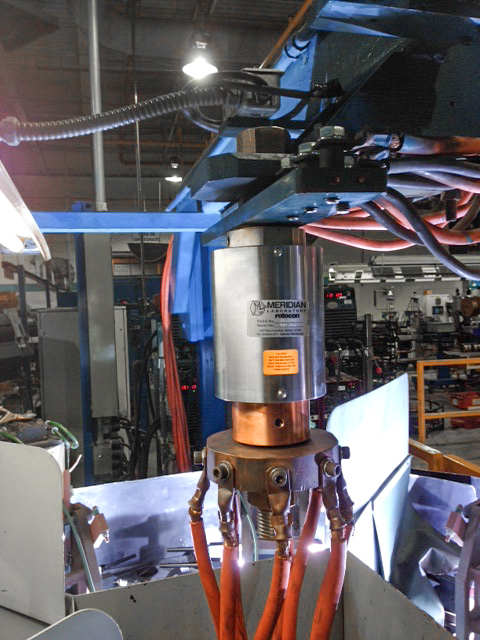

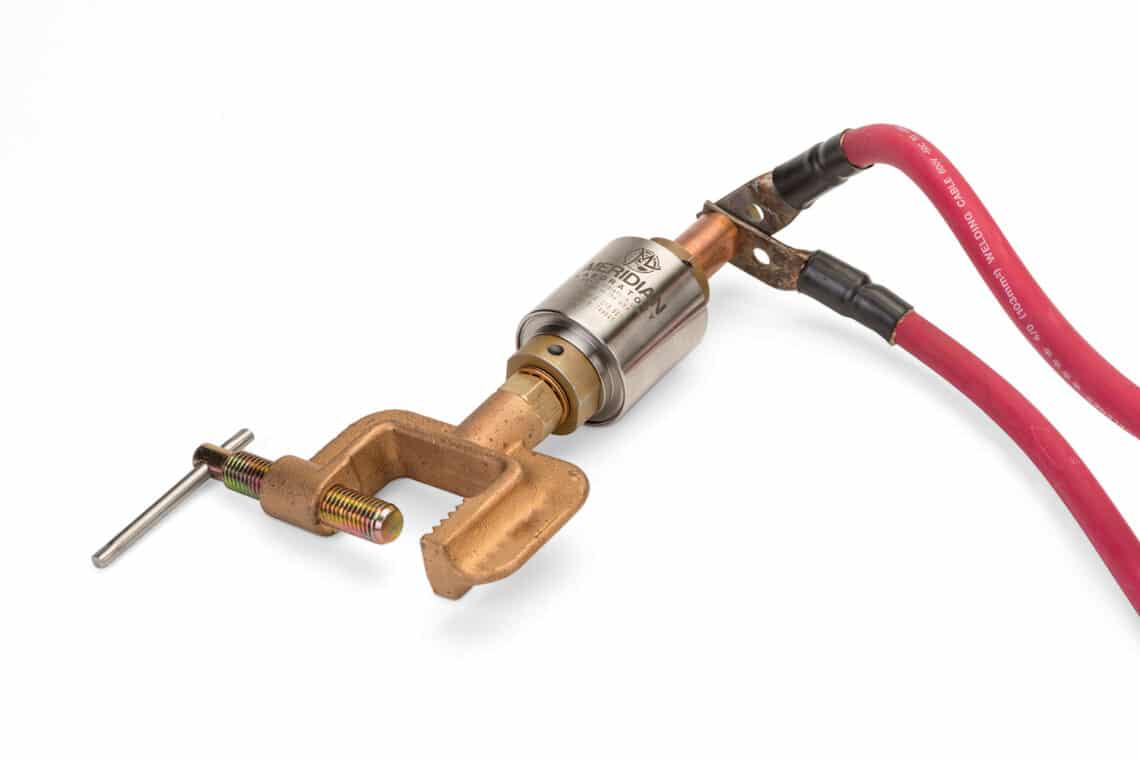

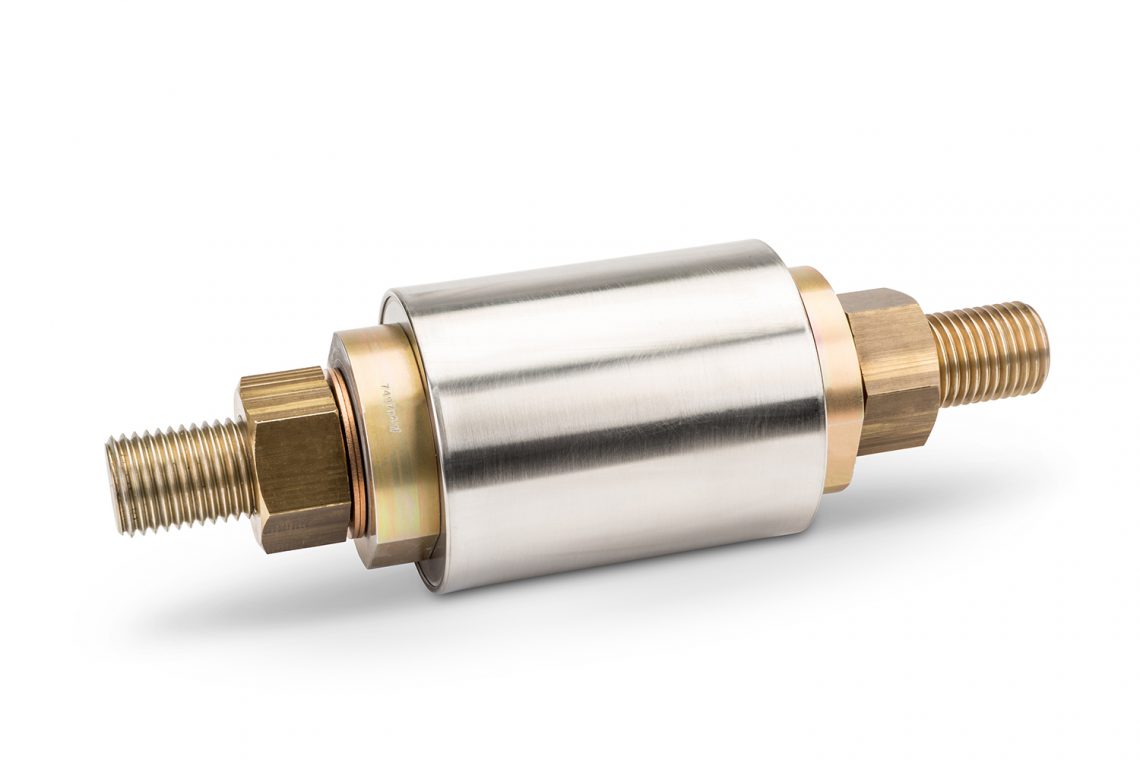

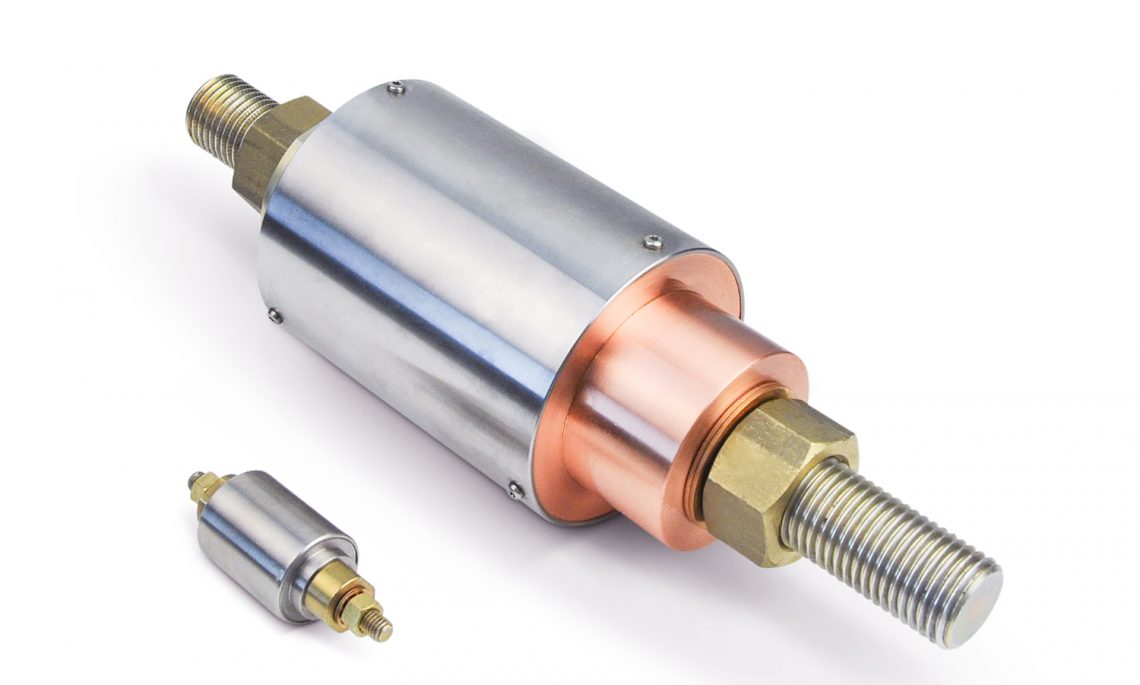

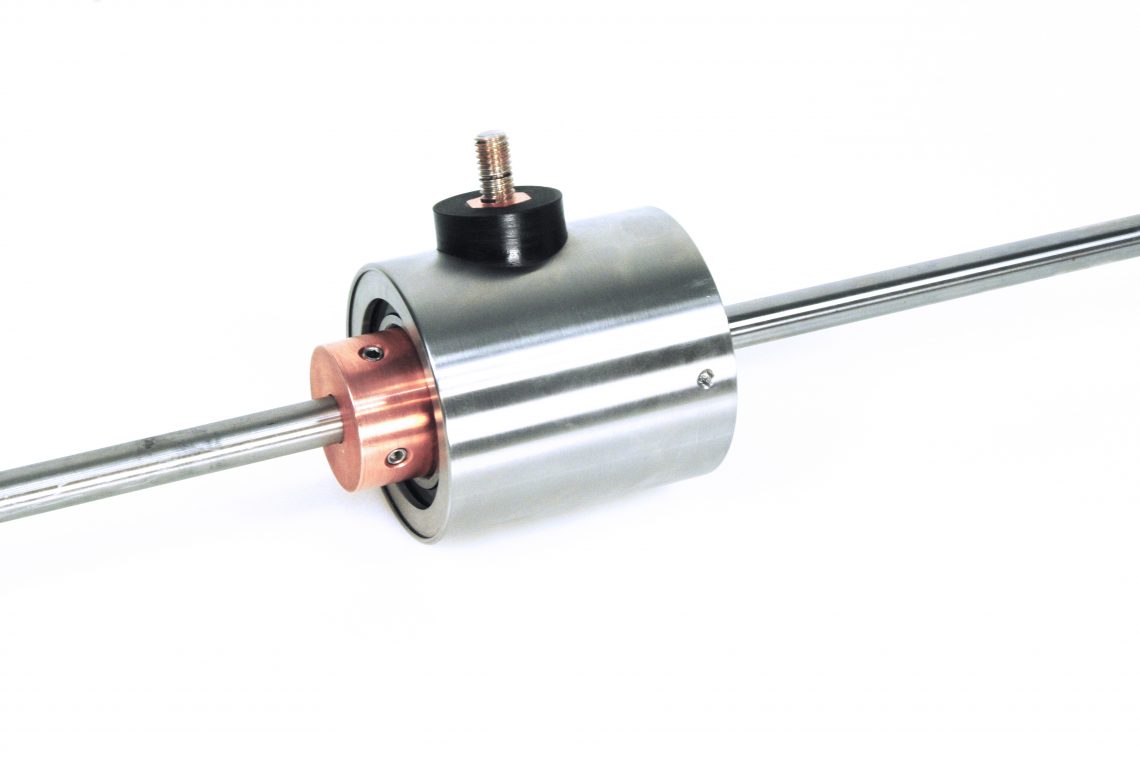

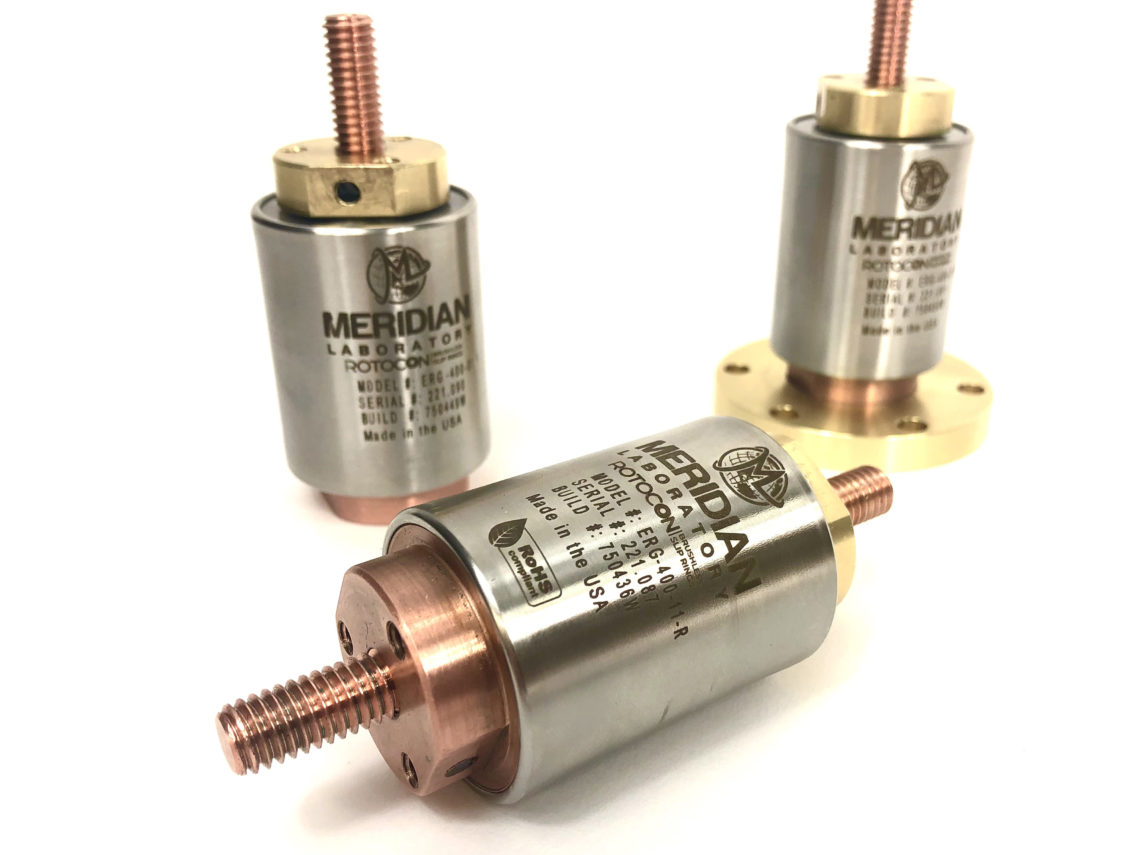

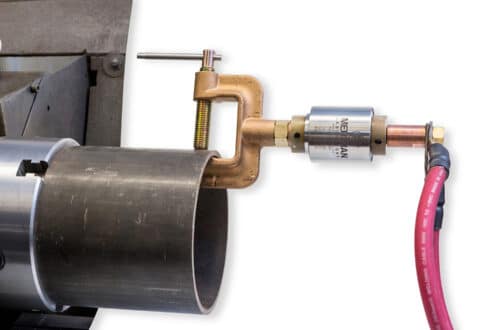

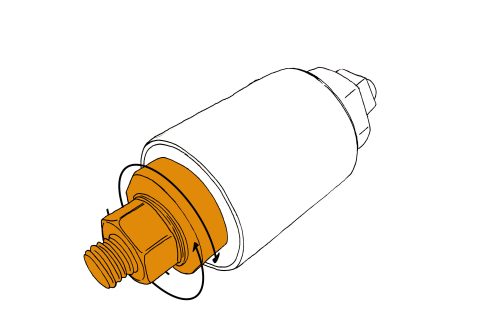

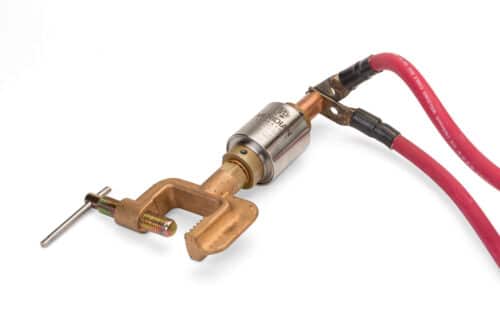

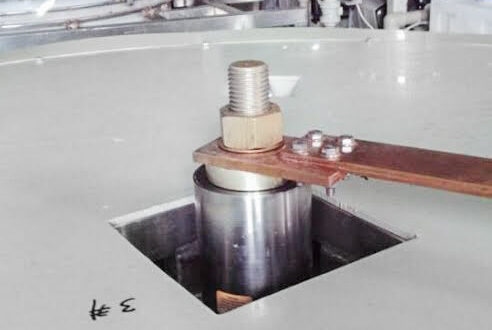

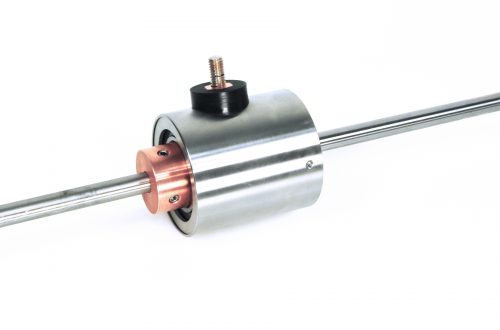

Suitable for all environments and applications including rotary welding, electro-plating, electro-polishing, cutting, and other high current rotating industrial applications, the ROTOCON ERG/MC & ERGT Series are designed to withstand 100% duty cycles in continuous manufacturing and production processes, without interruption or downtime. The ROTOCON’s brush-free design eliminates all issues such as maintaining brush contact and conductivity, does not require application of conductive greases, and eliminates elevated contact resistance associated with conventional brushed rotary grounds. With the ERG Series, you will achieve a more consistent ground, with zero fluctuations in resistivity, or elevated contact resistance over time and revolutions; this will lead to a better end product in rotational welding, plating, polishing, and other high current applications that require rotation. ROTOCON rotary grounds can be used interchangeably on the positive or negative (ground) of an application without any difference in performance.

Video: ROTARY GROUND SHOOTOUT : SUMNER ST-107, LENCO MODEL C, TWECO RG-140 VS. MERIDIAN LABORATORY ROTOCON® ERG-400 ROTATING ELECTRICAL GROUND

| RPM | Model dependent, see model specifications below* |

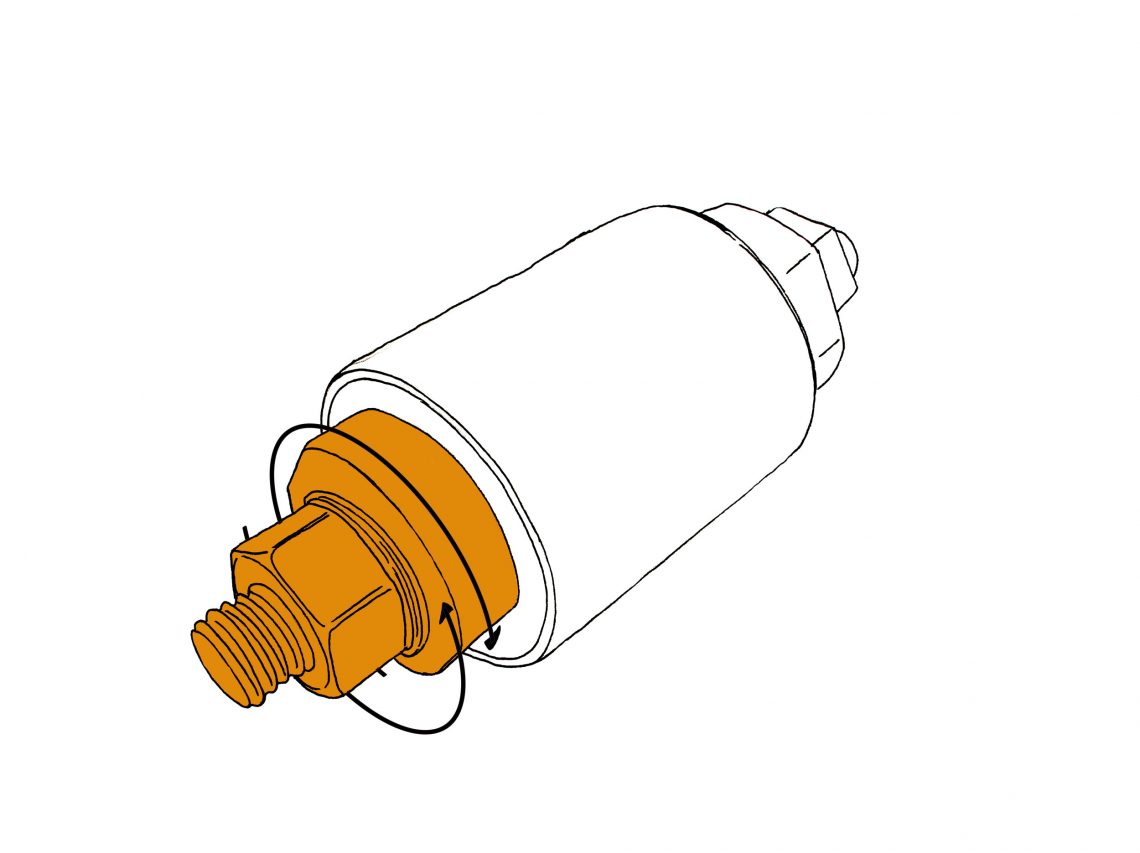

| MOUNTING | End of shaft with threaded stud or flange, or with set screws onto shaft (through-hole ERGT Series) Click here for installation and best practices video. |

| HOUSING | 304 Stainless Steel |

| OPERATION | Can be operated in any direction or orientation |

| MAINTENANCE | Features permanently lubricated bearings, brush-free design requires no user maintenance |

| AMPERAGE | Model dependent, see specifications chart - 100% overload allowed for <60 seconds |

| FREQUENCY | DC to 1GHz - Contact Meridian Laboratory for ampacity ratings at higher frequencies |

| STATIONARY CONTACT RESISTANCE | <0.01mΩ |

| ROTATING CONTACT RESISTANCE | Same as stationary contact resistance (<0.1mΩ) |

| ELECTRICAL NOISE | <0.01uV |

| OPERATION | Intrinsically immune to internal arcing |

| AMBIENT TEMPERATURE | Not to exceed 160˚F (70˚C) |

| IP RATING | Standard is IP65, Available up to IP68 |

| RoHS COMPLIANCE | Optional, RoHS /CE Compliancy Available |

- Custom mounting flanges

- Fiber Optic Rotary Joint (FORJ)

- Rotary Union

- Corrosion Protection (Gold Plate)